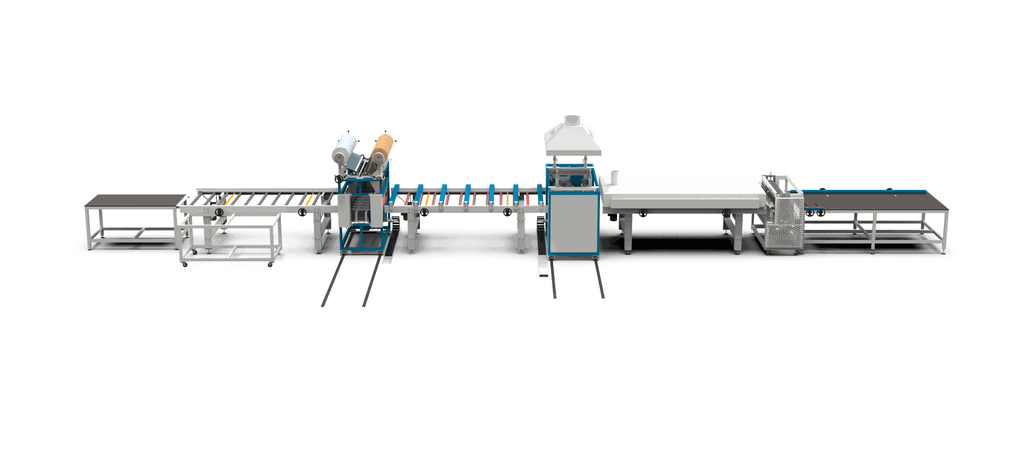

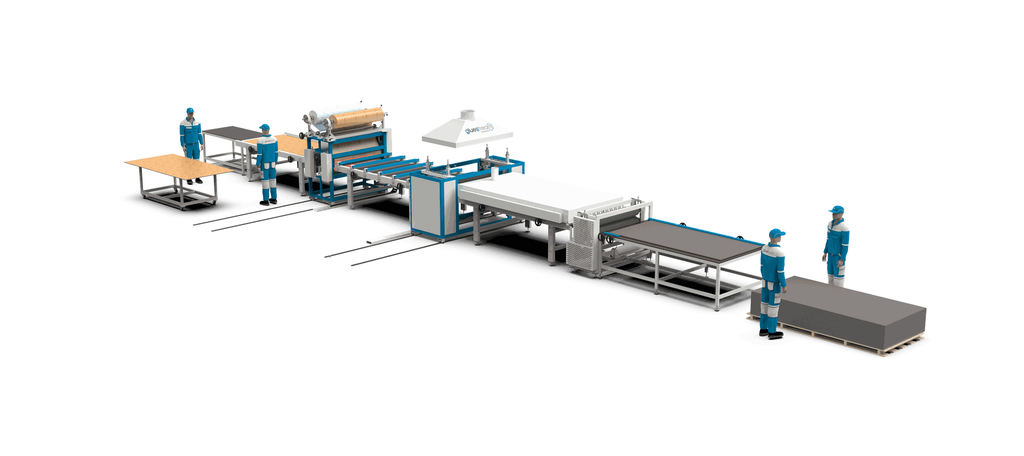

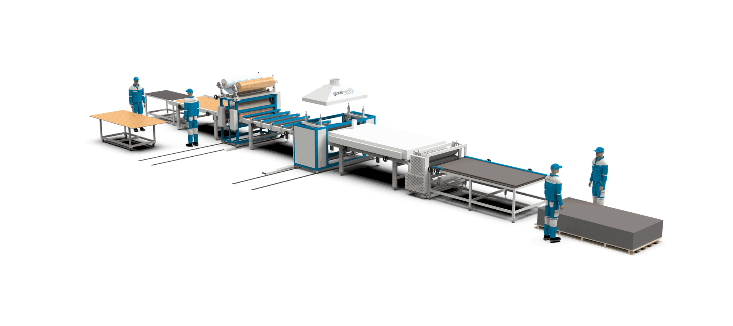

FLM-1500 linka na plochou laminaci hot melt PUR

Technologie: HOT MELT PUR & PSA TECHNOLOGIE PLOCHÉ LAMINACE

| Doprava: 16-18 týdnů |

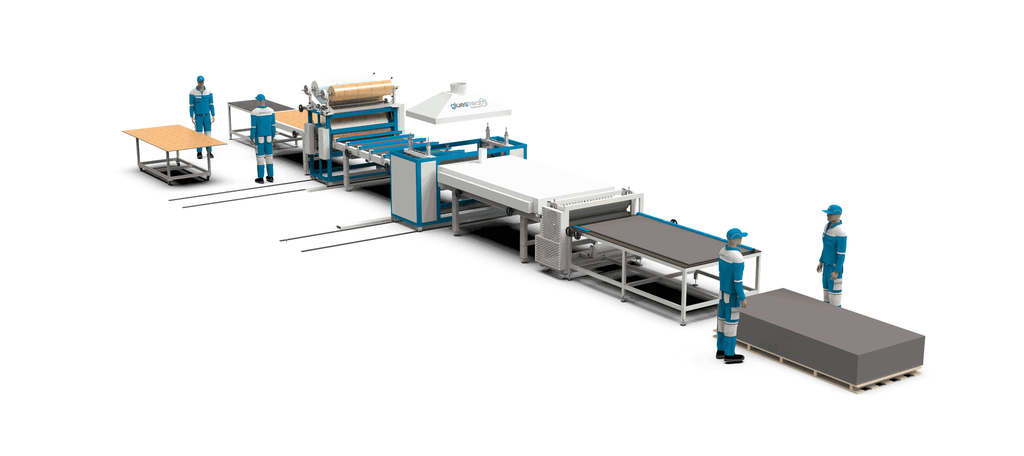

| Personál: čtyři pracovníci a jeden řidič vysokozdvižného vozíku |

| Rychlost nanášení lepidla m²/min: 10-15 |

| Napájení: podle regionu |

| Stlačený vzduch: 6-8 bar |

| WiFi modul: ANO, s technickou podporou 24/7 |

POPIS

Návrh strojů a komponenty

Návrh strojů se skládá z následujících klíčových komponentů:

•Automatická stanice pro zpracování primeru

•Tunel pro ohřev a sušení

•Aplikátor horkého válce

• Decorative Foil Applying System with a Heated Roller Press

• Protective Foil Applying Unit

•Stoly pro podávání a přijímání

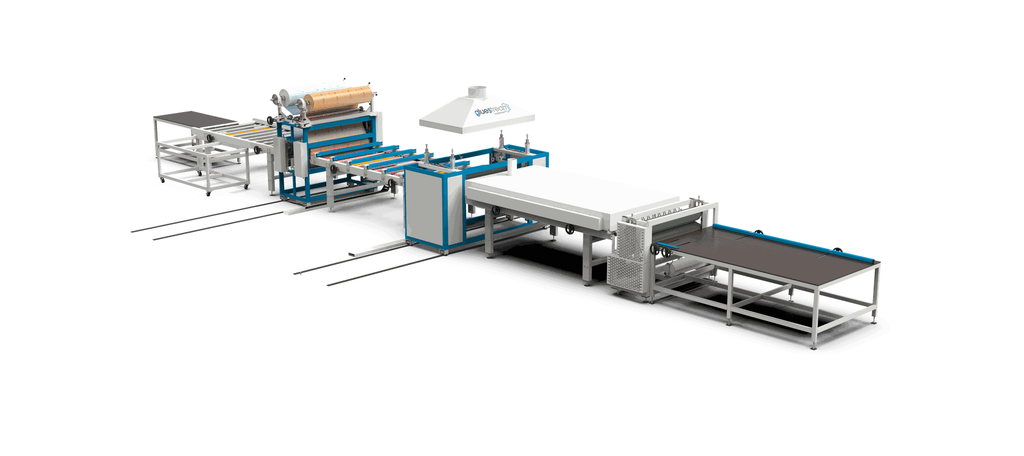

Tentostanice pro zpracování kapalného primeruje vybavenautomatický řídicí systém, který regulujedoba trvání a frekvenceaplikace primeru.

Tentovyhřívaný tunelzajišťujeodpařování kapalných složekz primeru a zahřívá laminované plechy napožadovaná teplota procesu, jak je specifikováno technologickým postupem.

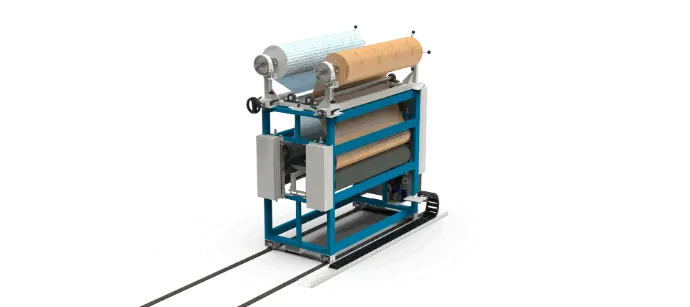

Jednostranný válcový nanášeč

Tentojednostranný válcový nanášečje vybavenvyhřívané dávkovací a nanášecí válce, speciálně navržené proTechnologie nanášení tavného lepidla PUR. To zajišťujepřesné a rovnoměrné rozložení lepidlapro vysoce kvalitní výsledky laminace.

The adhesive application unit features heated rollers with precise glue application adjustment. The machine can be equipped with an additional pre-melting station to enhance productivity or can operate without a melting station at speeds up to 3 m/min.

Jednotka pro nanášení dekorativní fólie

Tentojednotka pro nanášení dekorativní fóliese skládá zvyhřívané válcekteré přitlačují film na plechy, zajišťujícepřesná a bezpečná aplikace. Jednotka je vybavenasystém pro umístění fóliepro zajištění přesného zarovnání.

Tentofilmové rolejsou zajištěny pomocípneumatické svorky, atahová sílafólie může býtupravenépro dosažení optimálních výsledků aplikace.

Aplikace laminovaných plechů

•PVC-laminované plechyjsou široce používány při výroběPVC sendvičové panely, které jsou nezbytné provýroba dveří z PVC a hliníku.

•Laminované pozinkované ocelové plechyjsou běžně používány provýroba vstupních ocelových dveří. Tyto plechy mohou podstoupit další zpracování, jako jeohýbání, děrování nebo laserové řezáníbez poškozenídekorativní fólie.

Řídicí systém a aplikace

Tentořídicí systémlaminovací linky shromažďujeprocesní data v reálném časeze senzorů, což umožňuje operátorovisledovat a upravovatvšechny potřebné parametry pro optimální výkon.

Všechny stroje Gluestream jsou vybaveny modulem pro dálkový přístup, který zákazníkovi poskytuje 24/7 online internetovou podporu.

Prosím, kontaktujte nás, pokud potřebujete naši technickou podporu, a my se s vámi podělíme o naše znalosti.

Náš tým má velké zkušenosti s lepicí technologií, získané během let.

Pomocné stroje

Zařízení pro lepení laminátů je nezbytné v technologickém procesu. Prozkoumejte, jaké pomocné stroje naši zákazníci zakoupili pro zlepšení svých operací.

Alternativní produkty

Pokud máte zájem o pomoc s výběrem zařízení a potřebujete naši pomoc s vygenerováním poptávky po nákupu nebo s jakýmikoliv dalšími konkrétními dotazy, neváhejte nás kontaktovat!