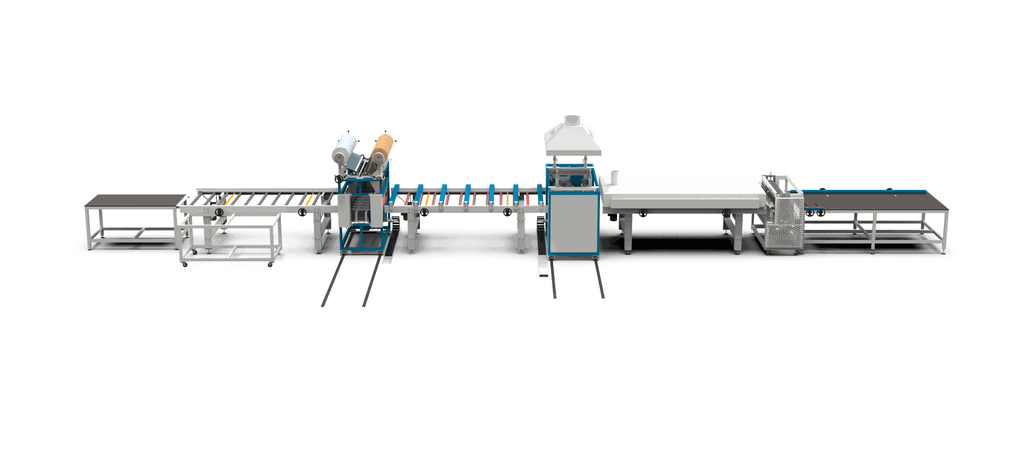

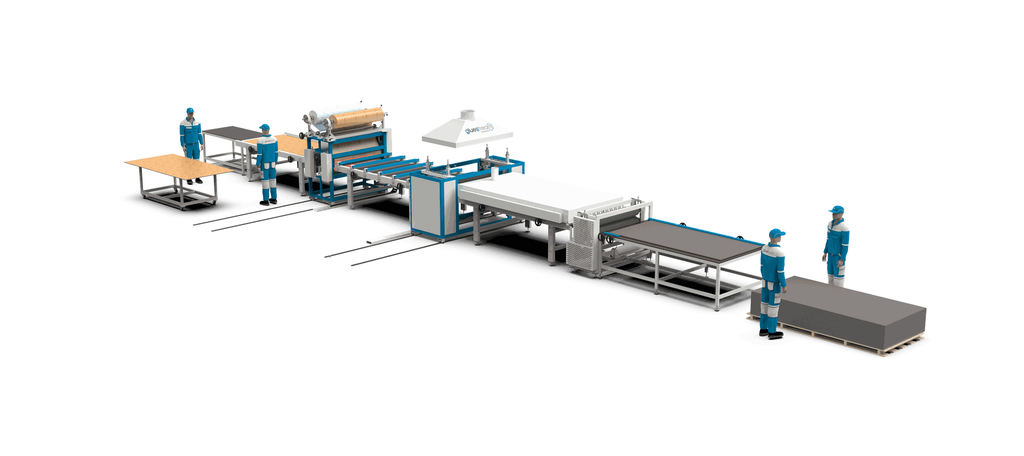

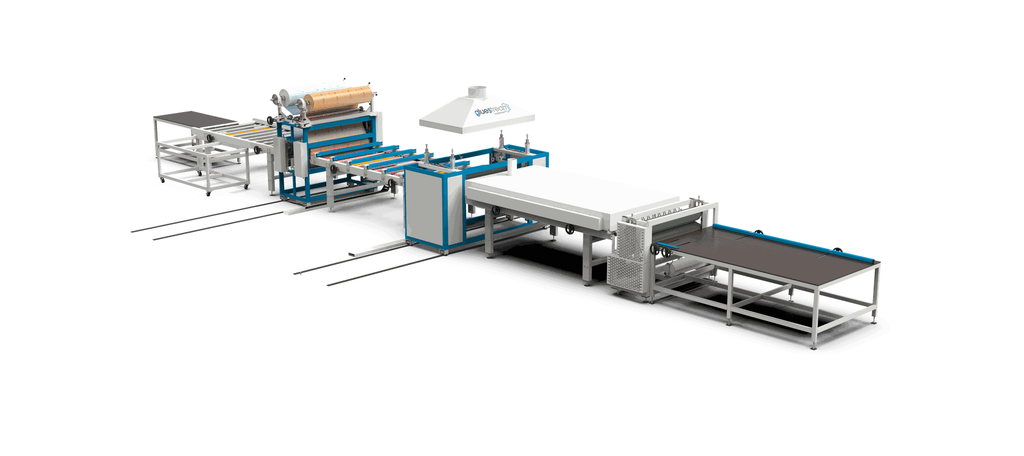

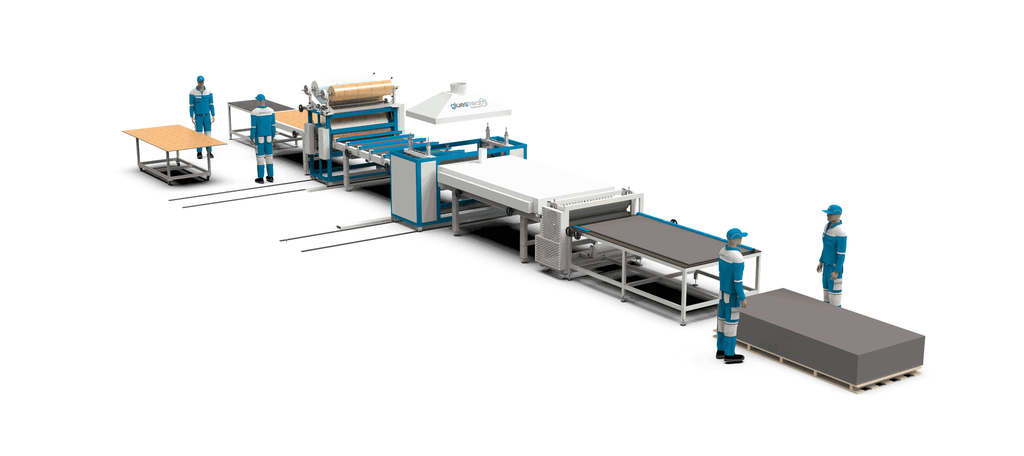

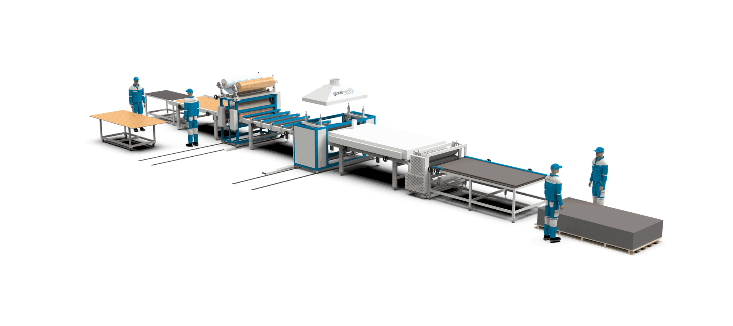

Ligne de laminage à plat FLM-1500 hot melt PUR

Technologie : TECHNOLOGIE DE LAMINATION À PLAT HOT MELT PUR & PSA

| Expédition: 16-18 semaines |

| Personnel: quatre travailleurs et un conducteur de chariot élévateur |

| Vitesse d'application de la colle m²/min: 10-15 |

| Alimentation électrique: selon la région |

| Air comprimé: 6-8 bar |

| Module WiFi: OUI, avec support technique 24/7 |

DESCRIPTION

Conception et composants de la machine

La conception de la machine se compose des composants clés suivants :

•Station automatique de traitement du primaire

•Tunnel de chauffage et de séchage

•Applicateur à rouleau chaud

• Decorative Foil Applying System with a Heated Roller Press

• Protective Foil Applying Unit

•Tables d'alimentation et de réception

Lestation de traitement du primaire liquideest équipé d'unsystème de contrôle automatique, qui régule ledurée et fréquencede l'application du primaire.

Letunnel chauffantassure leévaporation des composants liquidesdu primaire et chauffe les feuilles laminées jusqu'à latempérature de processus requise, comme spécifié par le flux de travail technologique.

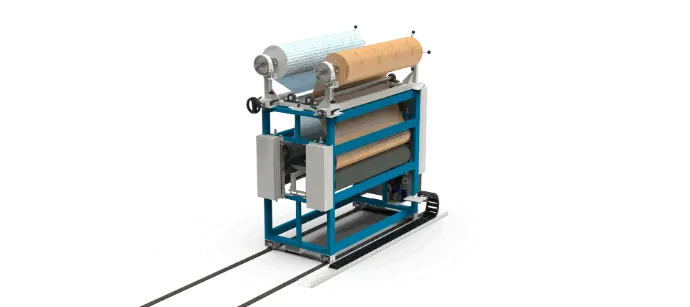

Enrobeuse à rouleau simple face

Leenrobeuse à rouleau simple faceest équipé derouleaux chauffants de dosage et d'application, spécialement conçu pourTechnologie d'application d'adhésif thermofusible PUR. Cela garantitdistribution précise et uniforme de la collepour des résultats de lamination de haute qualité.

The adhesive application unit features heated rollers with precise glue application adjustment. The machine can be equipped with an additional pre-melting station to enhance productivity or can operate without a melting station at speeds up to 3 m/min.

Unité d'application de film décoratif

Leunité d'application de film décoratifse compose derouleaux chauffantsqui presse le film sur les feuilles, assurant unapplication précise et sécurisée. L'unité est équipée d'unsystème de positionnement du filmpour garantir un alignement précis.

Lerouleaux de filmsont sécurisés en utilisantpinces pneumatiques, et leforce de tensiondu film peut êtreajustépour obtenir des résultats d'application optimaux.

Application de feuilles laminées

•feuilles laminées en PVCsont largement utilisés dans la production depanneaux sandwich en PVC, qui sont essentiels pourfabrication de portes en PVC et en aluminium.

•Feuilles d'acier galvanisé laminéessont couramment utilisés pourproduction de portes en acier d'entrée. Ces feuilles peuvent subir un traitement supplémentaire tel quepliage, poinçonnage ou découpe lasersans causer de dommages aufilm décoratif.

Système de contrôle et application

Lesystème de contrôlede la ligne de laminage recueilledonnées de processus en temps réeldes capteurs, permettant à l'opérateur desurveiller et ajustertous les paramètres nécessaires pour une performance optimale.

Toutes les machines Gluestream sont équipées d'un module d'accès à distance, offrant au client un support Internet en ligne 24/7.

Veuillez nous contacter si vous avez besoin de notre support technique et nous partagerons nos connaissances avec vous.

Notre équipe possède une grande expérience en technologie adhésive, acquise au fil des années.

Machines auxiliaires

Les équipements de collage stratifié sont essentiels dans le processus technologique. Découvrez quelles machines auxiliaires nos clients ont achetées pour améliorer leurs opérations.

Produits alternatifs

Si vous souhaitez obtenir de l'aide pour choisir votre équipement et si vous avez besoin de notre assistance pour générer une demande d'achat ou pour toute autre question spécifique, n'hésitez pas à nous contacter !