Formed-in-place-foamed gaskets (FIPFG) or Cured-in-place gaskets (CIPG) technology is based on applying liquid materials, which are cured and foamed in the place where they were applied. Two-component polyurethane foam and silicone are usually used.

We mainly specialize in 2-C PU foamed materials.

Polyurethane gaskets are increasingly used to reduce the necessity of various sizes and shapes of gaskets and to make their sealing properties better, making them seamless.

Features and benefits:

- Applicable on both - flat surfaces and in grooves.

- Flammability according to UL94 HBF

- Hardness between Shore 35-80 is adjustable by keeping physical properties within requests.

- Low Shore Hardness and, therefore, low compression hardness.

- Very low density.

- Very good mechanical properties.

- Low water absorption – approx. 3%

- Indoor and outdoor usage in the range of -60°C to 80°C

- Fast curing with a tack-free effect in only 5 minutes

- High tear strength.

- Compression set of less than 5% even after 5 years.

As a result, FIPFG technology is widely used in the automotive, electronic, and lightning industries, where it is required to reach high sealing properties and IP protection.

We know how important our environment is, and we want to decrease the use of hazardous materials in technology. Our engineers created a water-cleaning system to decrease the use of solvents in the mixing head cleaning process.

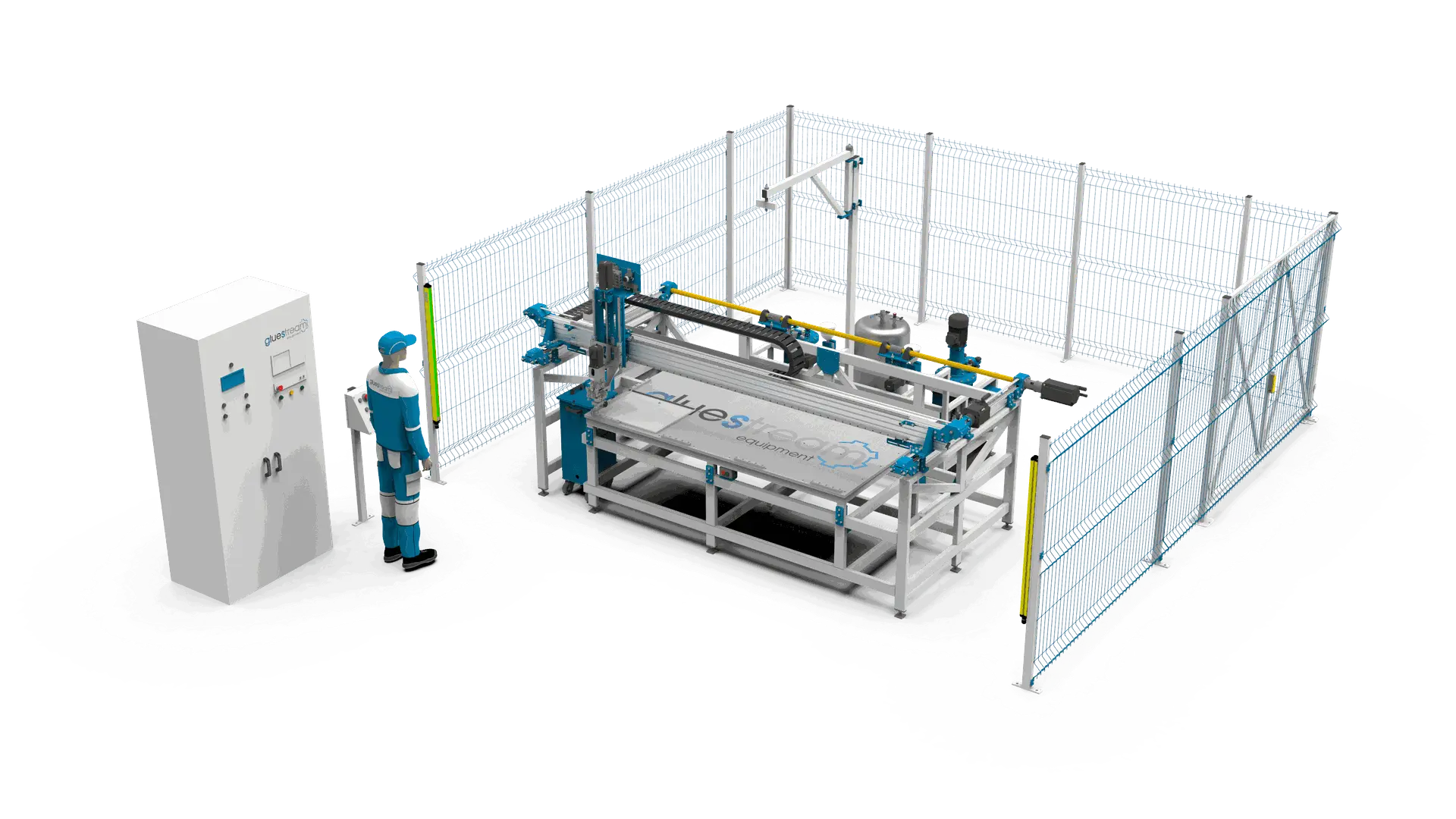

Are you looking for a polyurethane-applying machine that can handle 3D FIPG applications? Look no further than our advanced machinery designed to apply seamless gaskets in the XYZ axes with the utmost precision. Our machinery is easily controlled with a CNC operating system and can be installed in any manufacturing line, allowing it to work seamlessly with robotic arms or manipulators.

What’s more, we offer 24/7 technical support, available in every part of the world. Whether you need assistance with your machinery or guidance in creating a technological process, we’re always here to help.

FIPFG equipment