2-C and 3-C PUR adhesive applying technology

Two-component and three-component polyurethane adhesive precision dosing, mixing, and applying technology is widely used in manufacturing GFK sandwich panels.

A two-part polyurethane glue is cured by a chemical reaction between components A (polyol) and B (isocyanate).

The three-part PUR adhesive technology allows mixing component B with two different polyols, one fast-cured (A1) and another slow-cured (A2). We can modify the assembling and pressing time by changing the mixing ratio between components A1 and A2.

These advantages are used in refrigerated truck body panel manufacturing when producing small, simple, and large multi-layered panels.

The bonds are extremely strong and temperature—and water-resistant. Depending on the formulation, cured adhesives range from stiff and rigid to soft and flexible.

The adhesive can be low viscose, high viscose, and thixotropic to meet the usage requirements.

Predicted chemical reaction curing parameters allow it to be used in automatic modes by using cold or hot curing technology, adjusting the manufacturing process for more effective use.

Automatic equipment and software allow control and monitoring of the production process, with the possibility of remote access via the Internet for diagnostic and adjusting machinery.

Gluestream machinery is designed to use PUR adhesive in a wide range of viscosities from 1000 mPa*s to 350,000 mPa*s.

It is essential for the two required components to be dosed in the correct mixing ratio. Our pumps provide high accuracy of the glue dosing despite the difference in the adhesive viscosity, allowing them to work in a wide temperature range.

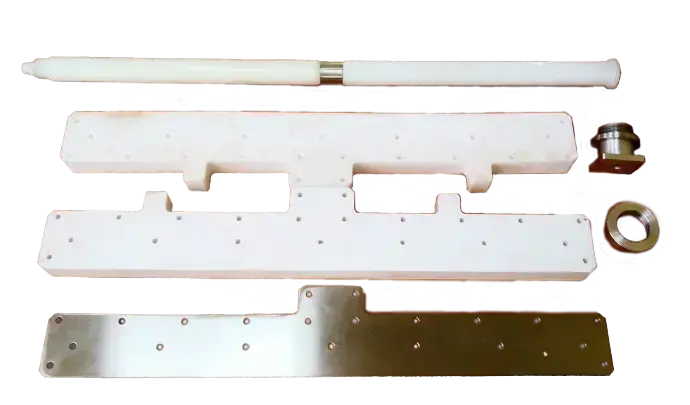

Mixing the components occurs in the static mixer, providing a homogeneous process of the components.

How to clean the machine?

The components are mixed directly in the static mixer, so the reaction start is possible in the mixer and a glue applicator. The static mixer can be cleaned or changed on a new one, the head has a disassembling structure, and the cured adhesive is easily removable from the inside.