What is PUR hot melt technology?

PUR (Polyurethane Reactive) hot melt adhesive is a versatile and strong adhesive used in various industries for bonding materials. PUR adhesives have high water and temperature resistance, there is no chance to re-melt it, that makes PUR using in various industrial fields.

View ProductsReactive polyurethane hot melt adhesives are used, for example, in bonding different types of plastic materials. They are also used in flat lamination PVC and steel sheets with decorative PVC foils, in furniture parts production, textile industry for cleaning sponges manufacturing, automotive industry, woodworking industry, wooden parquet manufacturing, and PVC windows profile wrapping. Compared to traditional hot melt adhesives, having a flat molecular structure, PUR has a 3D molecular lattice, penetrating the bonded materials and “stitches” them together. Due to the properties of the PUR adhesive, glued materials can be used in difficult weather conditions.

Here's an overview of its application technology:

Melting. PUR adhesive is supplied in solid form, packed in hermetic drums, and filled with nitrogen gas to replace any air inside. There are several types of melting stations, depending on the required melting capacity and glue volumes, from a few liters to two hundred liters. The PUR melters are specialized equipment that maintains precise temperatures to ensure the application of adhesive viscosity. Proper equipment maintenance is crucial to prevent blockages and ensure consistent adhesive application.

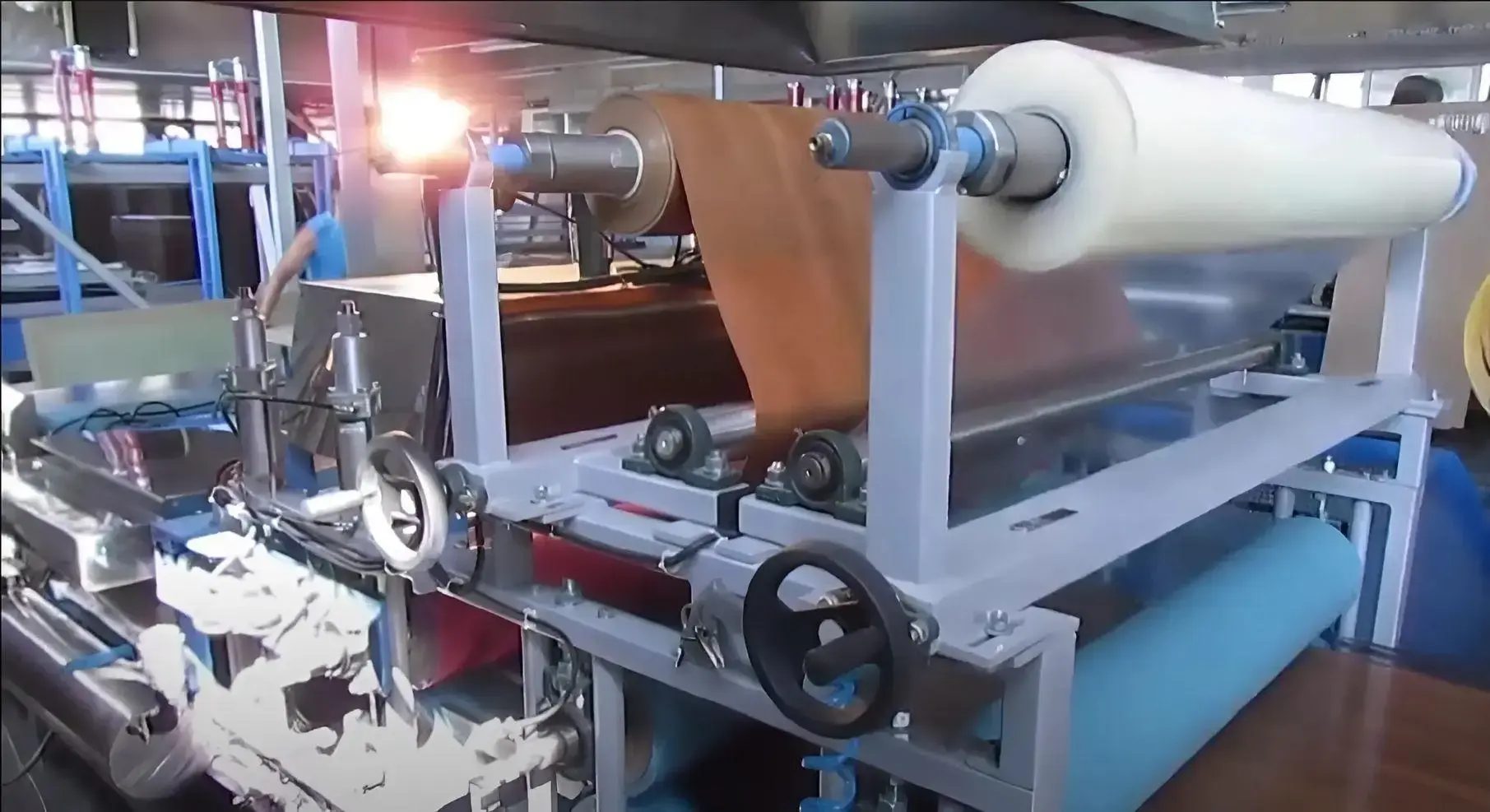

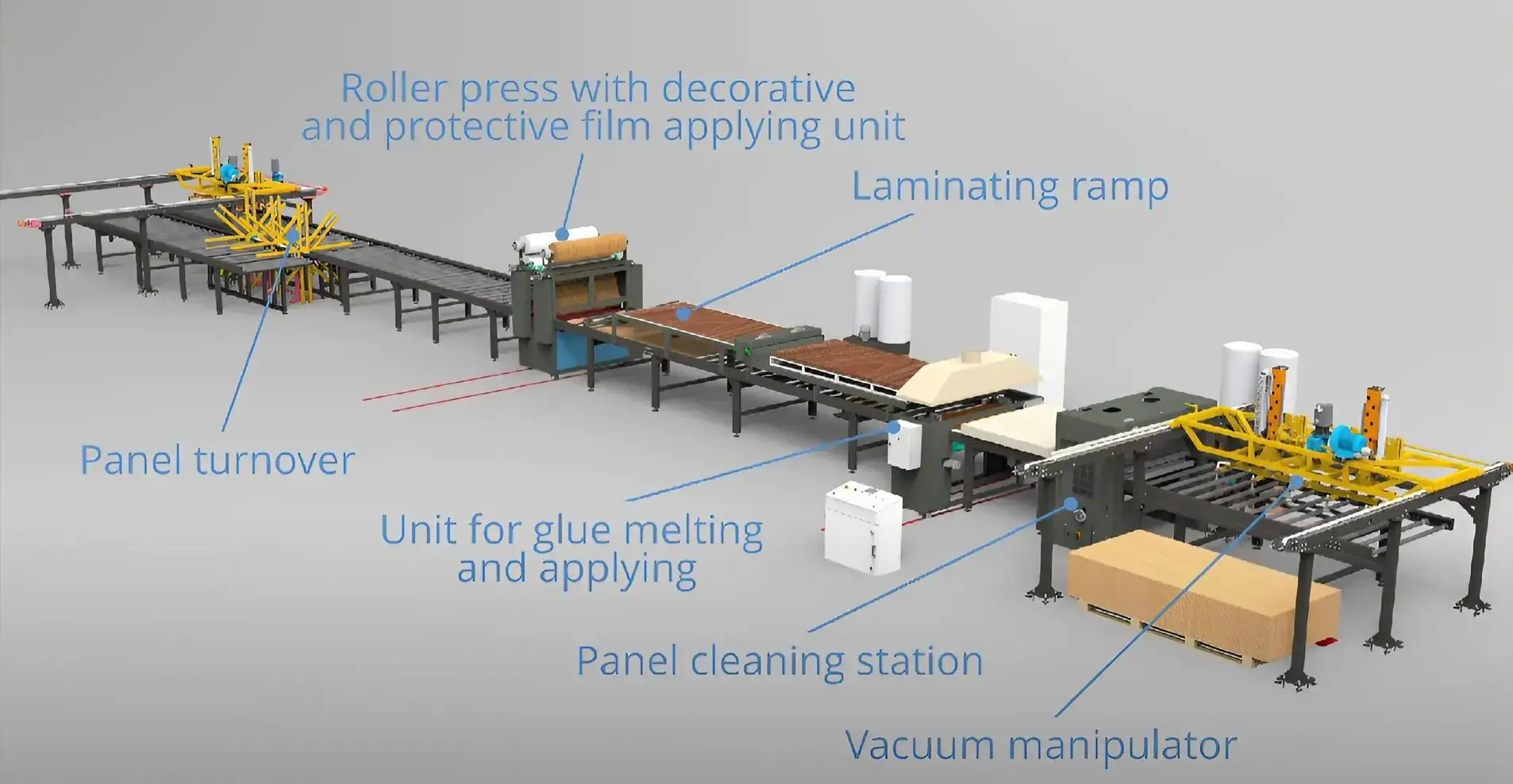

Application. The adhesive is dispensed in hot, liquid form using various equipment like rollers, nozzles, or spray systems. Application methods depend on the materials being bonded and the application's specific requirements.The melted adhesive is applied to one or both substrates and they are aligned and pressed together to initiate bonding.

The working temperature of the glue-applying is 130℃-140℃. PUR hot melt adhesive’s properties vary according to the substrates; it may have a higher initial strength if you need to fix the substrates, or it may be soft and elastic. The glue parameters can be modified depending on the materials and technological process.

Curing. Hot melt polyurethane reactive adhesives react with the bonded materials' moisture or air moisture. There are two stages of curing PUR hot melt: the first is a physical effect of cooling and solidifying the liquid adhesive, and the second is a chemical reaction of complete curing, allowing it to reach high bonding properties.

Substrates preparation. It is a very important stage to reach optimal bonding quality and strength. Substrates should be clean and dry. Most of the plastic substrates require priming. Priming may be chemical or physical. Chemical primers can be water-based or solvent-based. Physical priming is based on corona or plasma treatment of the substrate's surface.

Advantages of Polyurethane Reactive adhesive:

- Excellent heat and cold resistance, which makes it possible for indoor and outdoor using;

- Hight water resistance and many chemicals resistance;

- Extremely strong and durable bondings, suitable for structural applications;

- Safety of the adhesive using in hygienic products and various home using products;

- High bonding performance is achieved with low adhesive consumption;

- Fast initial durability, allowing to use PUR adhesive in automatic process;

- Solvent free technology to save environment and three-fold reduction of the logistics costs associated with transportation and storing of the adhesive.

PUR adhesives stand out for their superior bonding capabilities and resistance to environmental factors, making them ideal for heavy-duty and structural applications, while other adhesives might be chosen for simpler, less demanding tasks.