Vacuum press for GFK truck body panels

GFK panels, caravan panels, and refrigerated truck body panels manufacturing technology

| Shipping: 6-10 weeks |

| Power supply: according to the region |

| Dimensions: at request |

DESCRIPTION

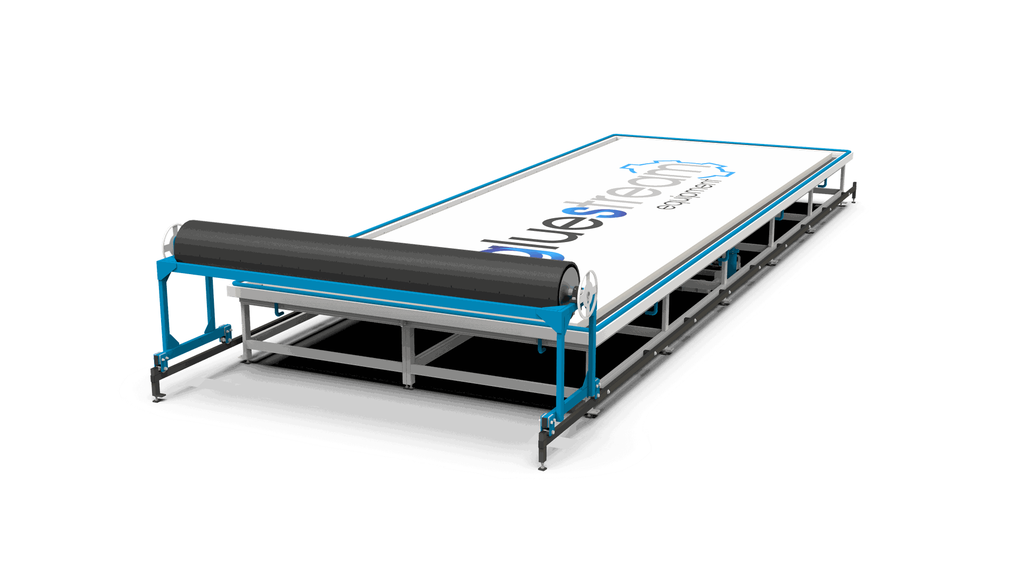

The press consists of:

• A vacuum table

• A vacuum membrane installed on the unwinding unit

• A two-level vacuum system, including a vortex fan and a vacuum pump, ensuring fast and stable vacuum generation

• Customizable dimensions based on request, with experience in manufacturing vacuum presses up to 14 meters in length and 3.2 meters in width

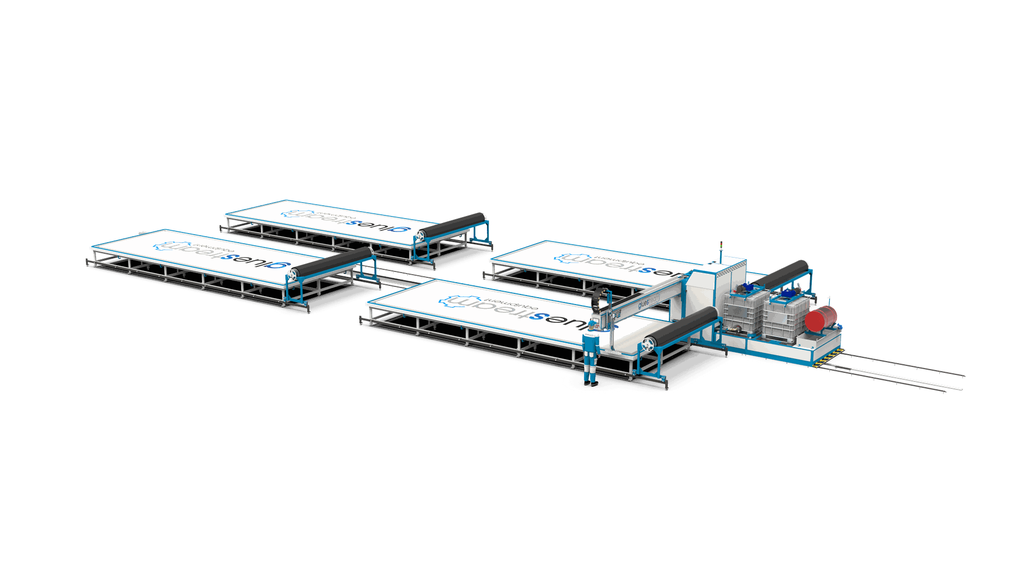

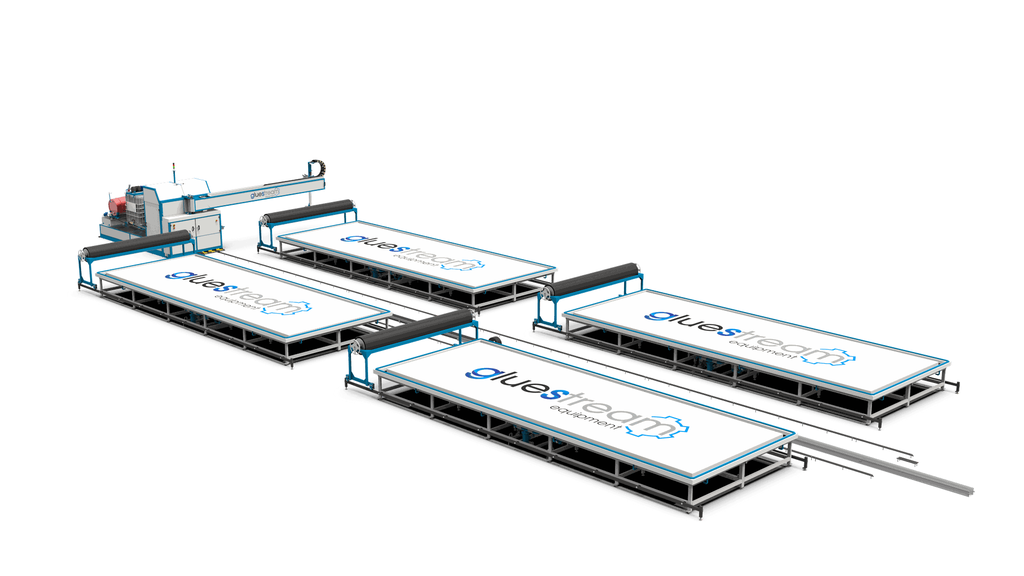

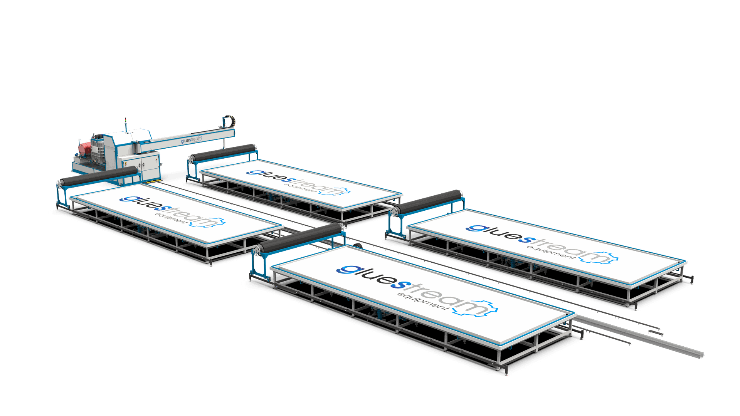

The presses can be located in two rows from both sides of the glue-applying machine SPL-11.

The vacuum press can be equipped with an automatic control system that enables:

• Automatic saving and display of pressing parameters (real-time vacuum depth, timing, and number of tables) on the control panel

• Automatic generation and registration of panel identification numbers in the system

• Automatic calculation of pressing time based on the adhesive’s parameters

• Automatic stopping of the pressing process once the set time has elapsed

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products

If you're interested in getting help with choosing equipment and need our assistance with generating a purchase inquiry or any other specific questions, feel free to contact us!