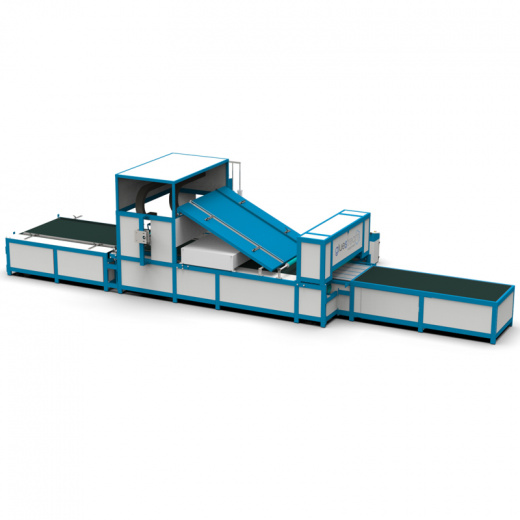

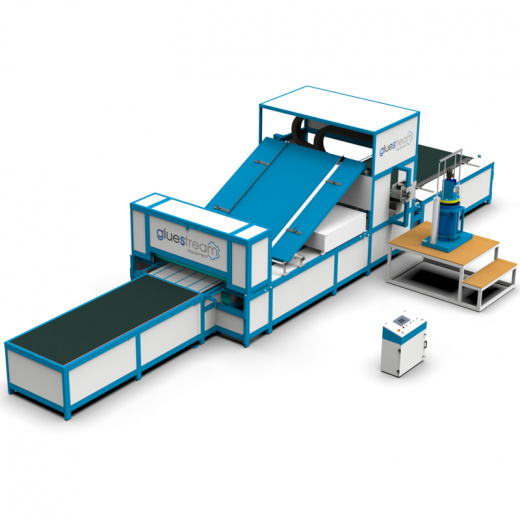

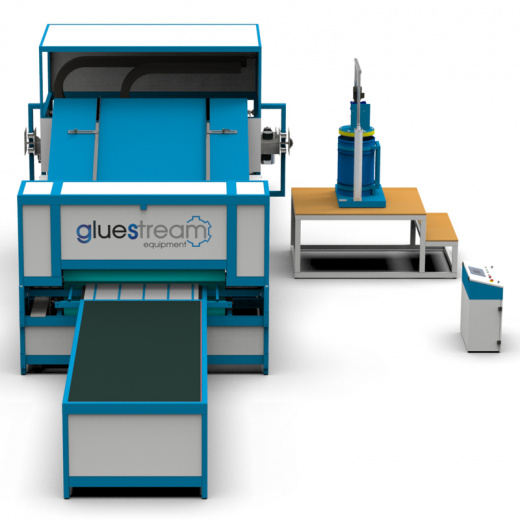

FLM-1100.SP - kitchen sponge production line. Hot Melt PUR adhesive-applying machinery

HOT MELT PUR & PSA FLAT-LAMINATION EQUIPMENT

DESCRIPTION

There are such advantages as:

- solvent-free adhesive technology;

- fast curing;

- presses are not required;

- possibilities to cut the mat on pieces right after cooling down;

- low glue consumption;

- safety for the personal.

Machinery design consists of such parts as:

- Roll unwinding unit;

- Belt conveyor;

- Adhesive applying unit with movable spraying heads;

- Hot Melt PUR drum melting station;

- Control system based on SIEMENS PLC;

- Heating tunnel;

- Inclined table for elastic polyurethane foam boards feeding;

- Roller press;

- Output table.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Your Dynamic Snippet will be displayed here...

This message is displayed because youy did not provide both a filter and a template to use.