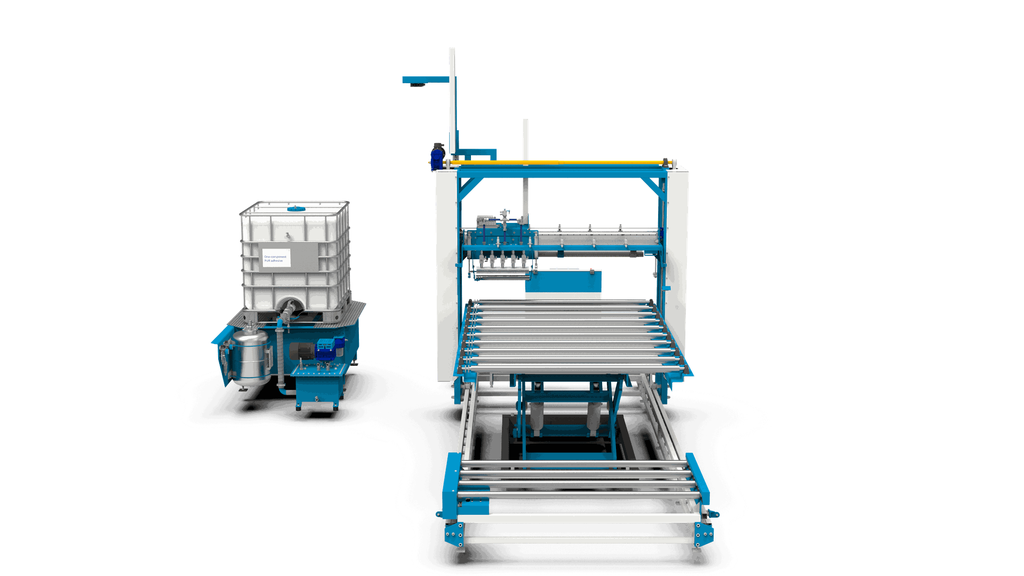

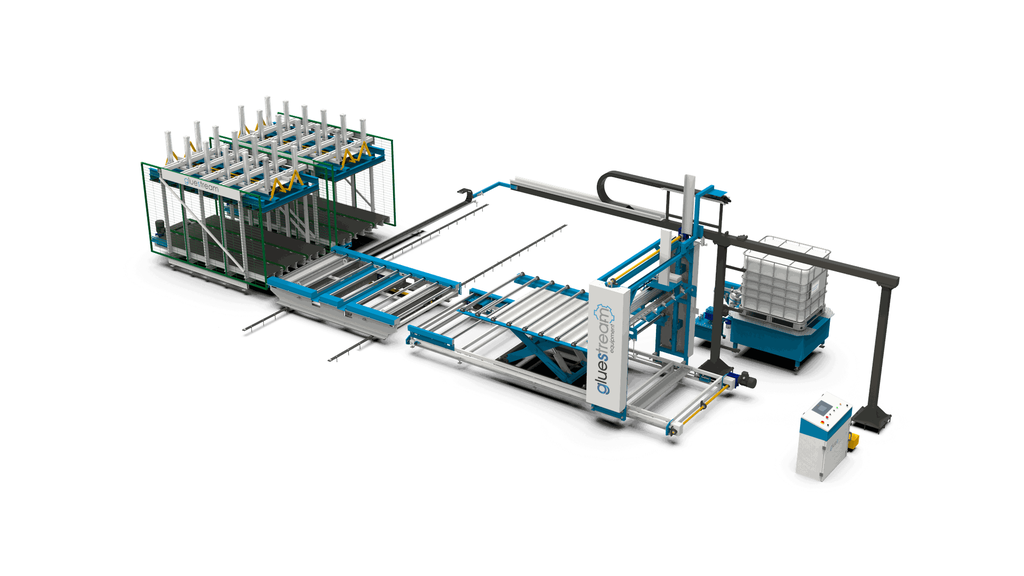

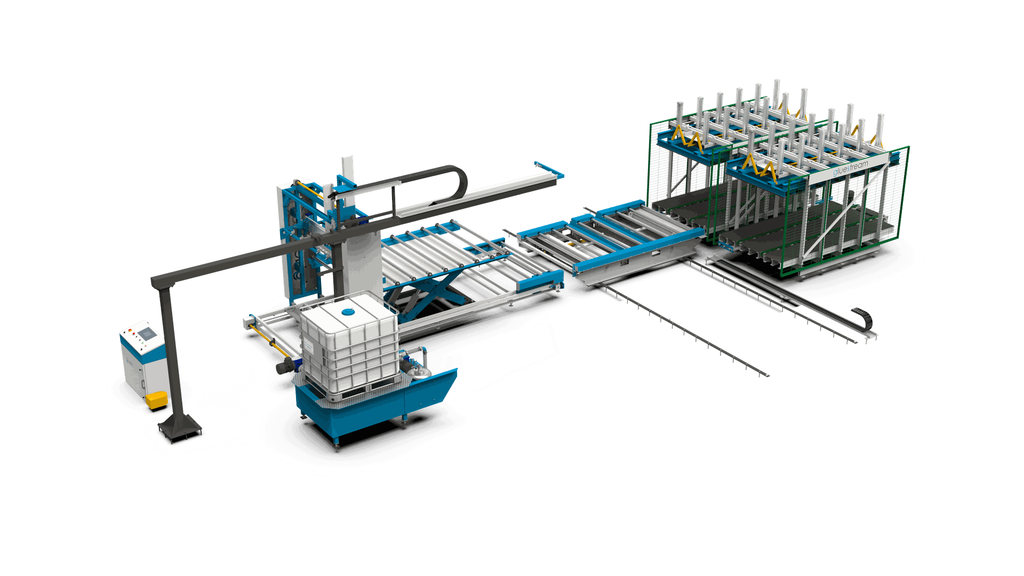

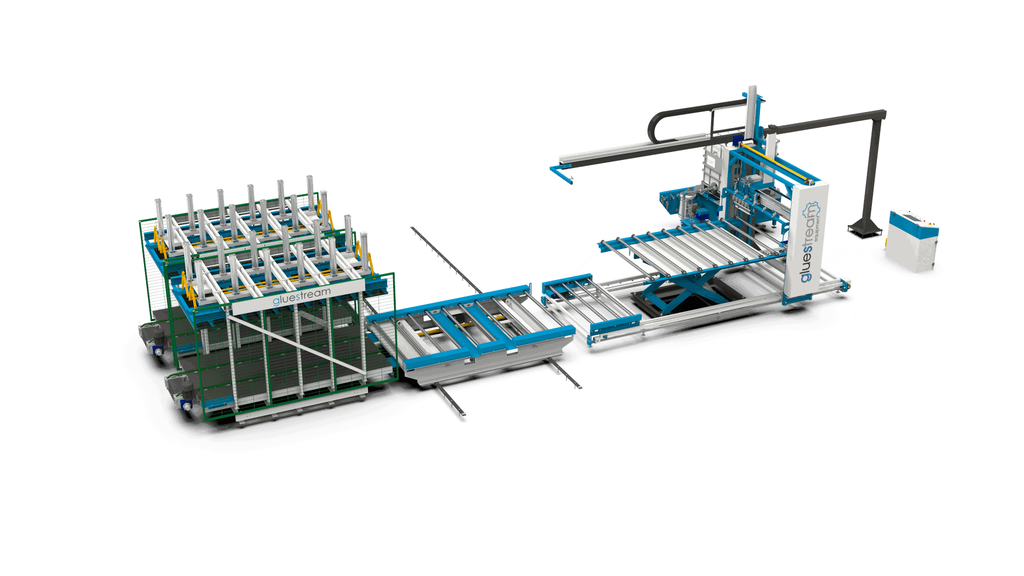

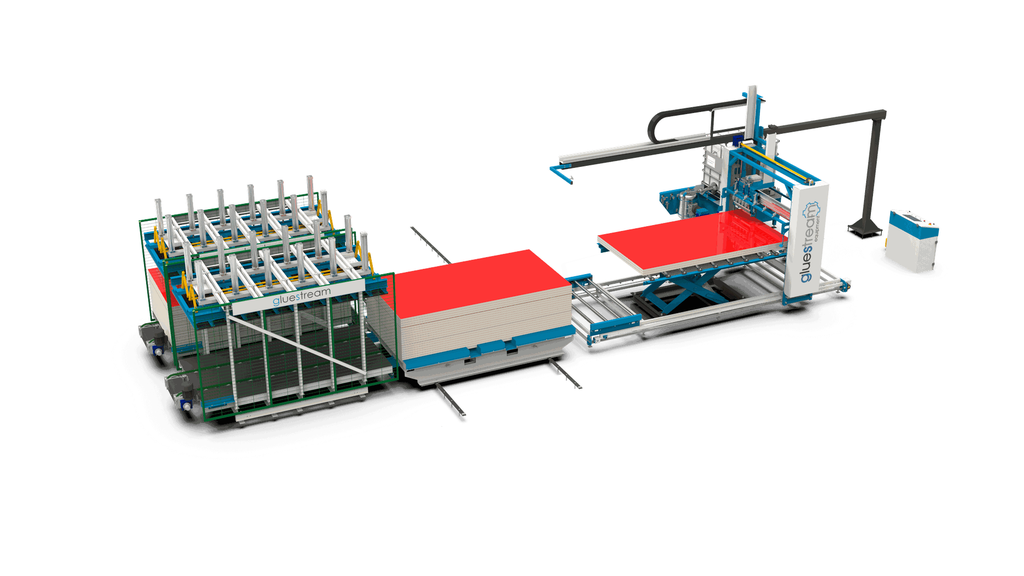

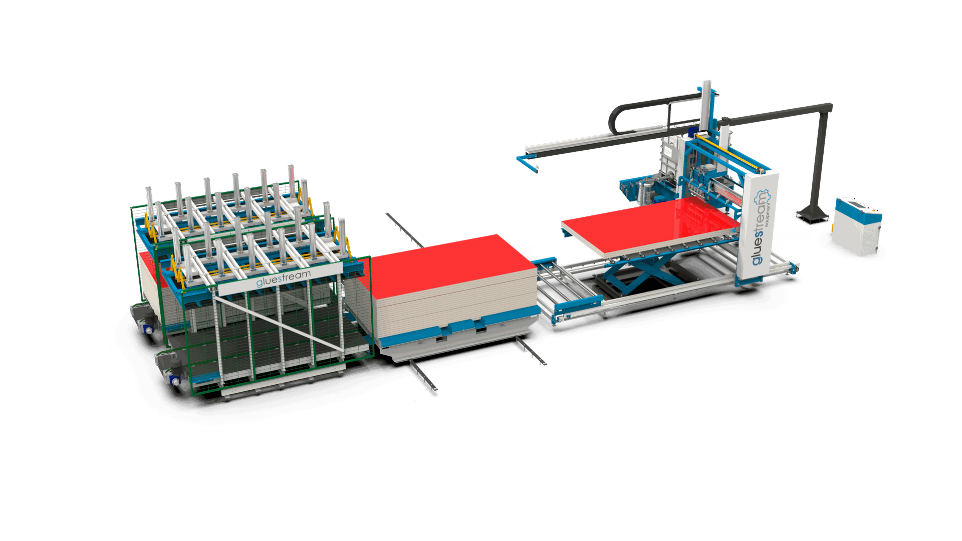

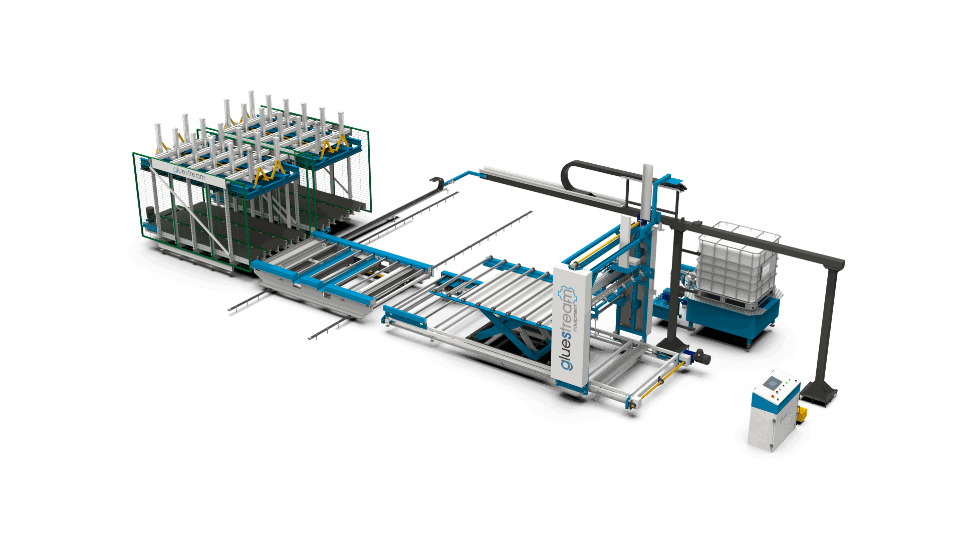

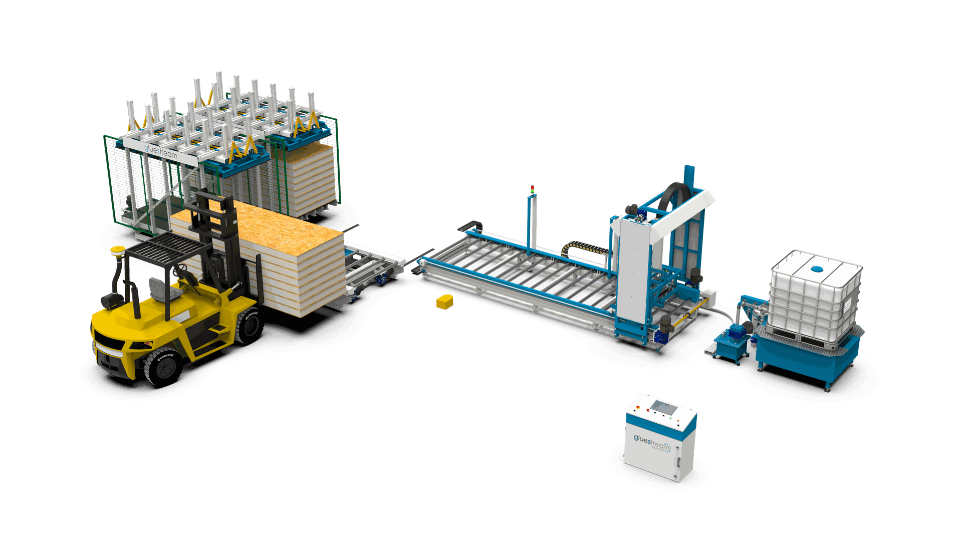

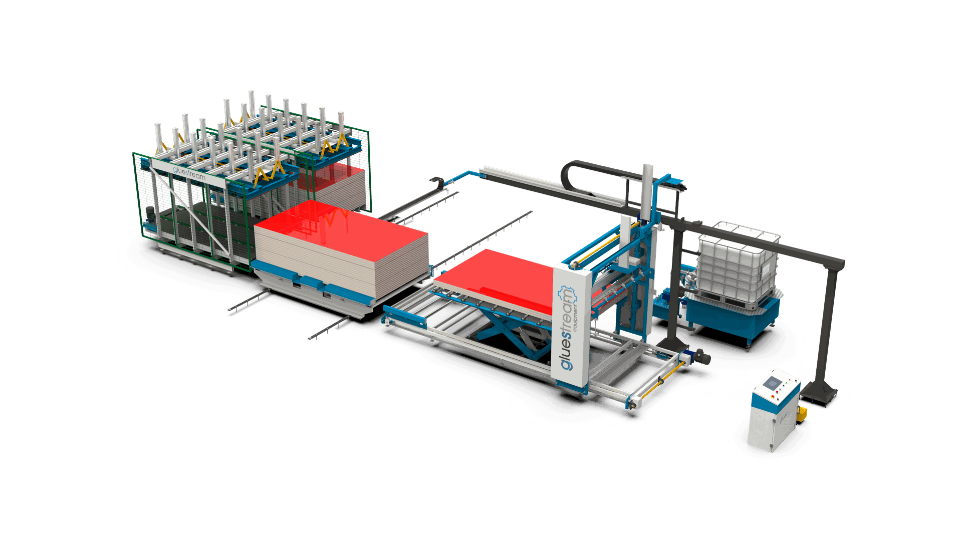

ASPL-10M.FH.2P sandwich panel production line with scissors lift

Technology:ONE-COMPONENT MOISTURE CURING PU APPLYING TECHNOLOGY

| Shipping: 16-18 weeks |

| Personnel: two workers |

| Production capacity, per 8h shift: 100-150 panels |

| Glue-applying speed sq.m/min: 10-15 |

| Power supply: according to the region |

| Compressed air: 6-8 bar |

| WiFi module: YES, with 24/7 technical support |

DESCRIPTION

Portal-type mobile polyurethane adhesive extruder (SPL-10M): This component is pivotal in applying adhesives precisely and efficiently to various materials, enhancing bonding quality for diverse combinations. The portal-type design ensures movement flexibility, covering broad production lines with ease.

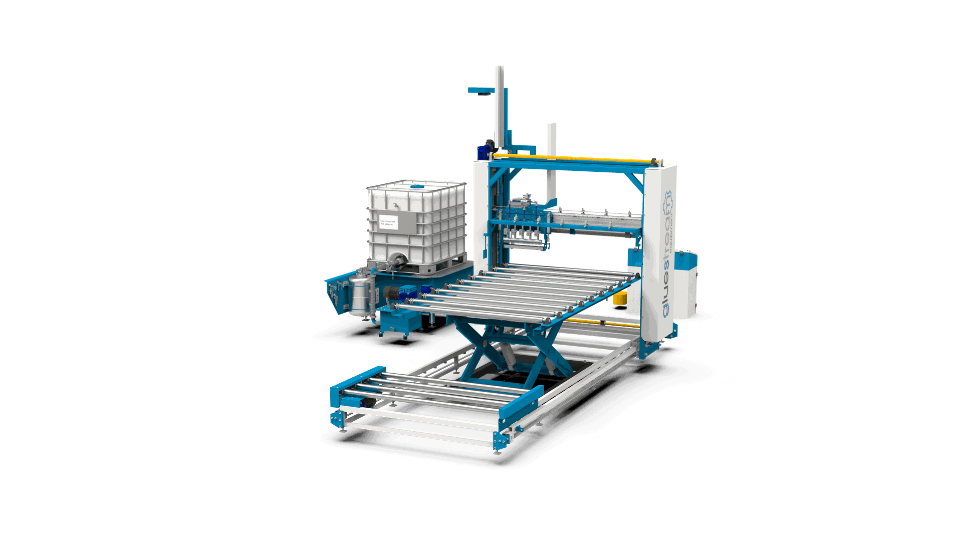

The KAM-PRO series adhesive applicator features two-way pneumatic valves and an auto-closing shutter tray filled with plasticizer, adjustable for power failures or manual control.

GLUESTREAM precision adhesive dosing pumps are crafted from specially treated metal with minimal gaps of up to 6 microns, lacking traditional seals and bearings for durability, and utilize frequency converters to automatically adjust dosing rates, even compensating for viscosity changes to maintain glue consistency within ±5 g/m².

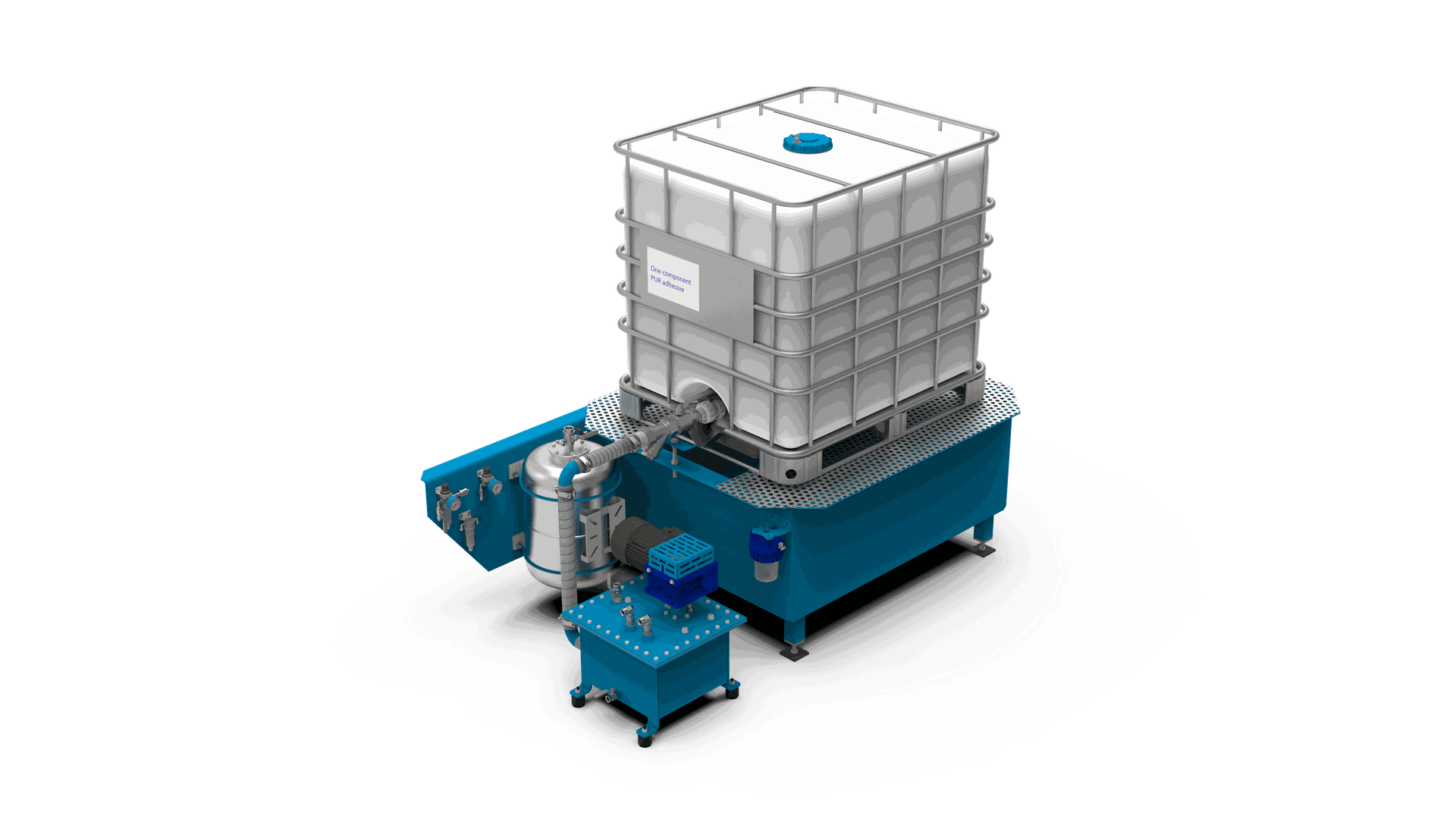

The adhesive is applied using PTFE jets spaced 8-10mm apart, with adjustable gluing width changes via valves or jet replacements within a minute. Automatic shutters prevent polymerization during standby, operating in Start/Stop mode. The pump station supplies adhesive from a main tank or drum using a gear dosing pump system, utilizing chemical-resistant high-pressure pipes.

Sandwich panels are transferred to an unloading zone post-pressing for forklift pickup.

The line may be completed with Jib-Cranes, operated by one worker.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products

If you're interested in getting help with choosing equipment and need our assistance with generating a purchase inquiry or any other specific questions, feel free to contact us!