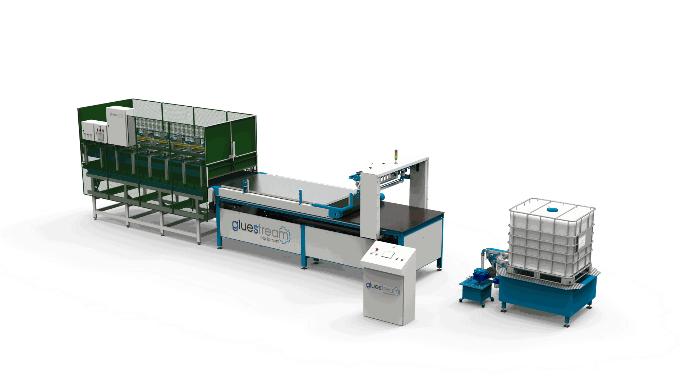

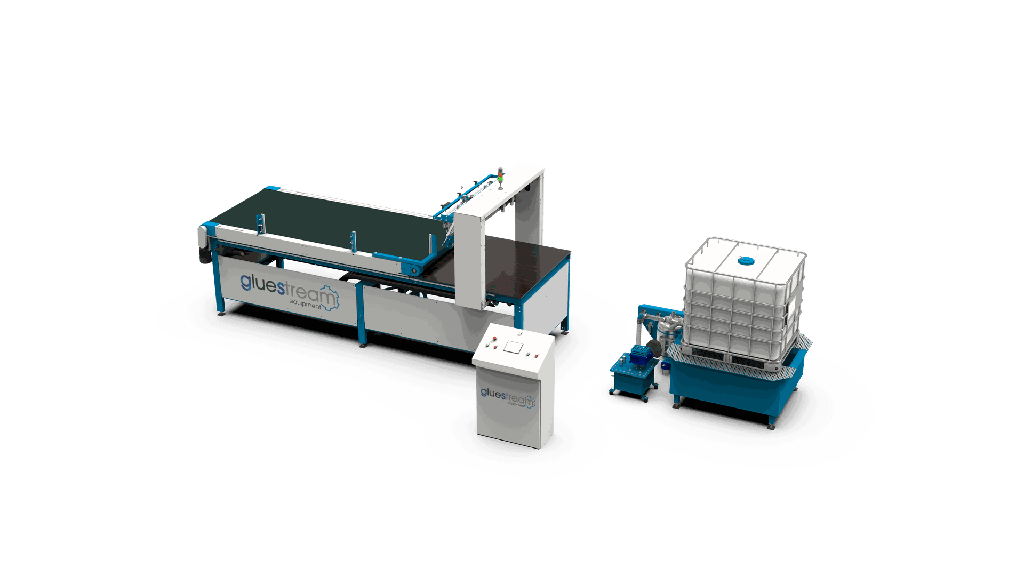

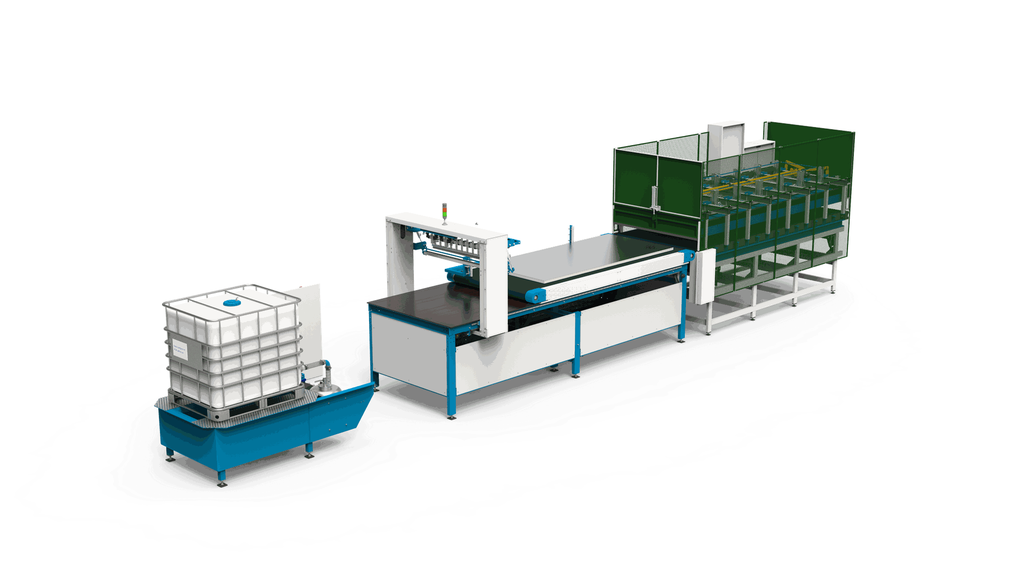

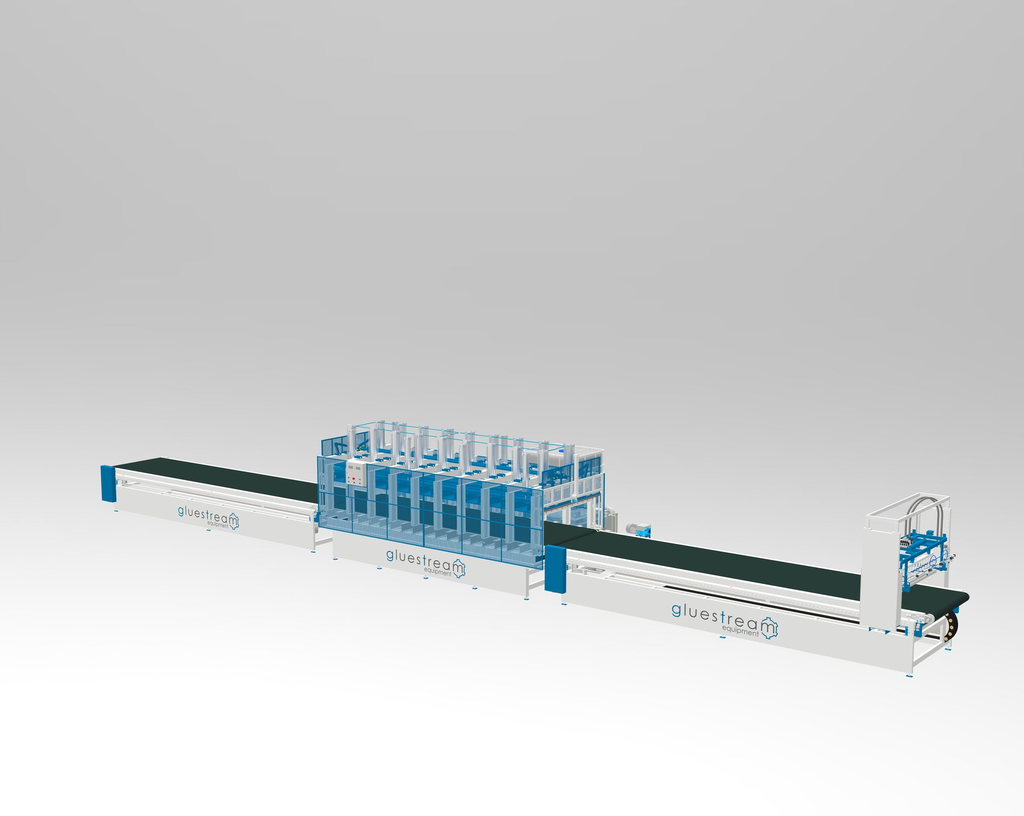

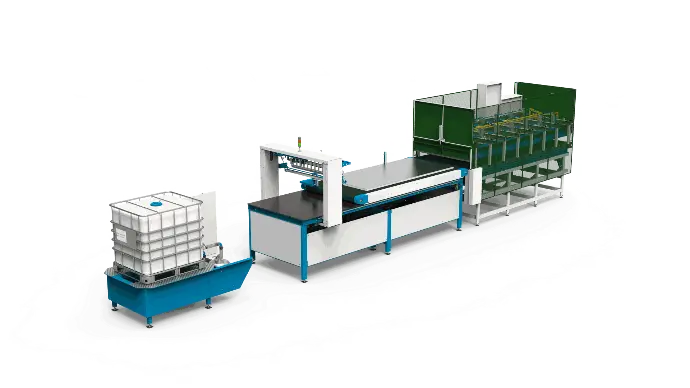

SPL-9.BC.1-C PUR adhesive-applying machine

Technology: ONE-COMPONENT MOISTURE CURING PU APPLYING TECHNOLOGY. Automated dispensing systems for 1-component polyurethane adhesives. Ideal for continuous production processes in various industrial sectors

| Shipping: 16-18 weeks |

| Personnel: two workers |

| Glue-applying speed sq.m/min: 10-15 |

| Power supply: according to the region |

| Compressed air: 6-8 bar |

| WiFi module: YES, with 24/7 technical support |

| Belt conveyor: YES |

DESCRIPTION

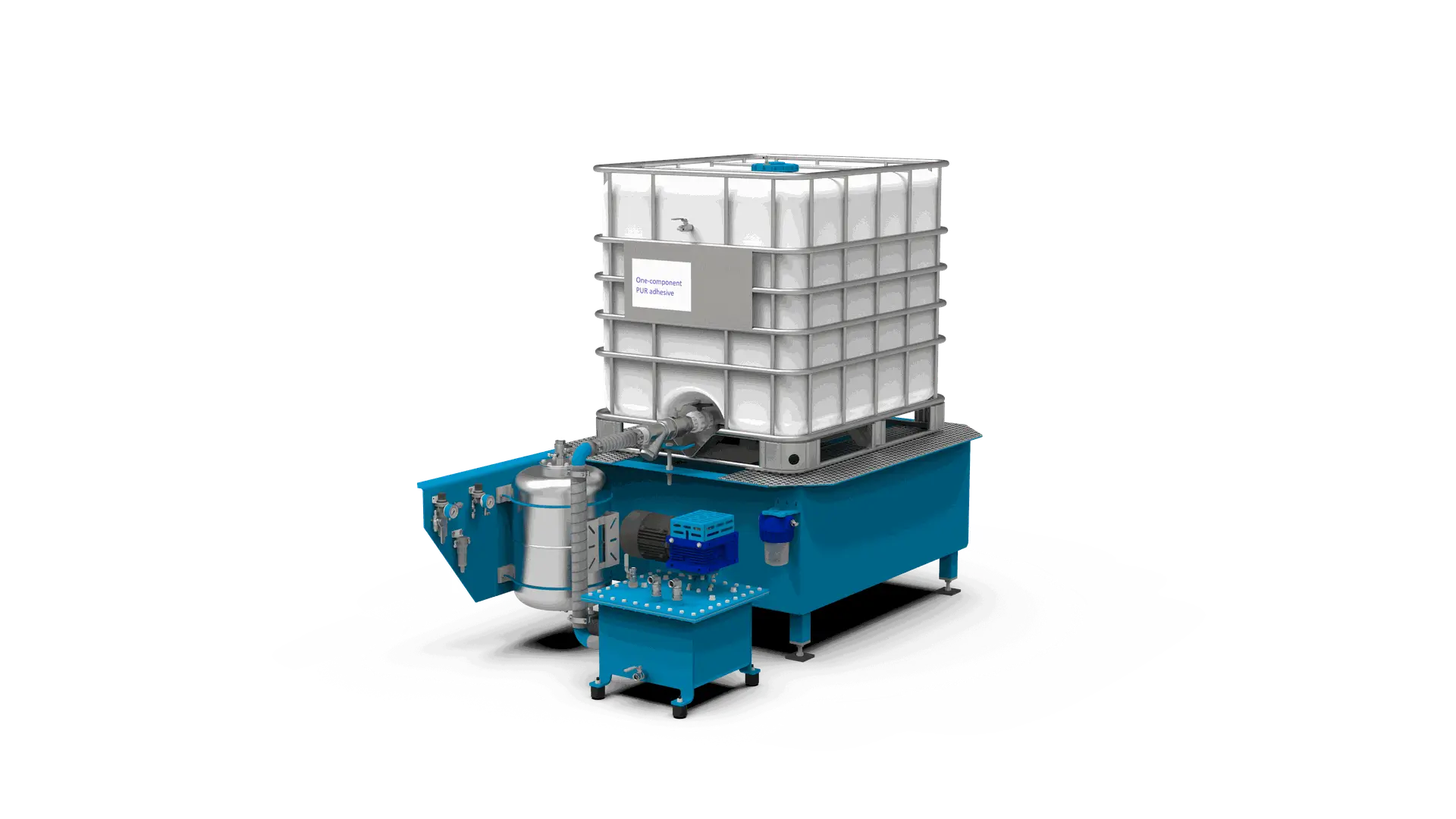

Due to the excellent bonding properties of 1-C PUR, it poses a risk to the components of the adhesive application system, as the curing reaction of polyurethane can easily initiate if moisture penetrates. Therefore, our machinery is designed to meet high safety standards and is completely sealed to prevent this.

Adhesive Application Adjustments:

- Automatically by length with a step of 1mm (standard method).

- Optionally, automatically by height with a step of 1mm.

- Automatically by width, with adjustments of 50/100mm by closing valves and 10mm by replacing the nozzle with a plug (with a stationary glue applying head)

- Automatically by width with a step of 1mm (max double applying area is 50mm). For the modification of the FH with of the FH with a movable "flying" head,

- Customizable according to specific customer requirements.

The machine is available in various modifications to meet diverse operational needs, including integration with a press station or installation for in-line processing via a belt conveyor.

Pump Station:

The high accuracy of positioning and automatic control ensures minimal adhesive loss. The adhesive is delivered using a high-precision dosing pump, applying the exact amount needed (±5g/m²). This system balances the variations in adhesive viscosity, allowing the use of one-component polyurethane adhesives from any manufacturer without the need for hardware reconfiguration.

SPL-9.BC Compatibility

The SPL-9 system can be integrated with various types of presses to optimize your production workflow, depending on your facility's logistics:

- C-Type Presses: Offers versatility and is ideal for operations requiring open-side access.

- Portal-Type Presses: Suitable for larger, more complex production layouts, providing robust support and stability.

Choose the configuration that best aligns with your production needs and enhances operational efficiency.

Explore Our YouTube Channel

Visit us on YouTube to see the SPL-9.BC adhesive extruder in action! Our videos showcase where and how it's used, providing insights and practical examples. Don't miss out on seeing our technology at work!

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Contact Us for Technical Support

If you require technical support, don't hesitate to reach out. We'll gladly share our extensive knowledge with you. Our team has years of experience in adhesive technology, ensuring you receive expert guidance and assistance.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products