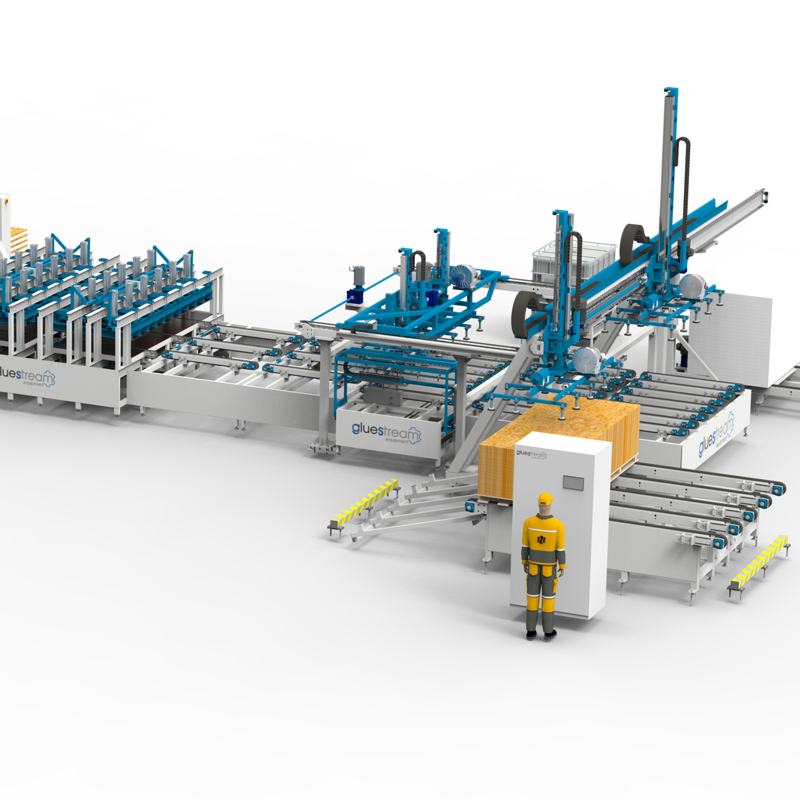

ASPL-3.1 BFT automatic SIP production line

ONE-COMPONENT MOISTURE CURING PU APPLYING TECHNOLOGY

| Personnel: one worker and a forklift driver |

| Shipping: 24 weeks |

| Production capacity, per 8h shift: 160 - 200 panels |

| Power supply: according to the region |

| Compressed air: 6-8 bar |

| WiFi module: YES, with 24/7 technical support |

DESCRIPTION

ASPL -3.1.BFT consists of:

- Feeding conveyors, where materials, placed on pallets, are located.

- Automatic manipulating portal, which takes materials from the pallets and moves them in the adhesive applying area.

- Automatic adhesive applying portal with a high accuracy manipulator, which assemble the panels with accuracy 0.2 mm.

- Pneumatic press.

- Automatic manipulator, designed to take the ready-made panels and put them on pallet.

- Workers - Two employees, an operator and a forklift driver.

Production capacity has to be calculated for each type of panels and can be modified depends of the customers’ requests and technological process.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products

If you're interested in getting help with choosing equipment and need our assistance with generating a purchase inquiry or any other specific questions, feel free to contact us!