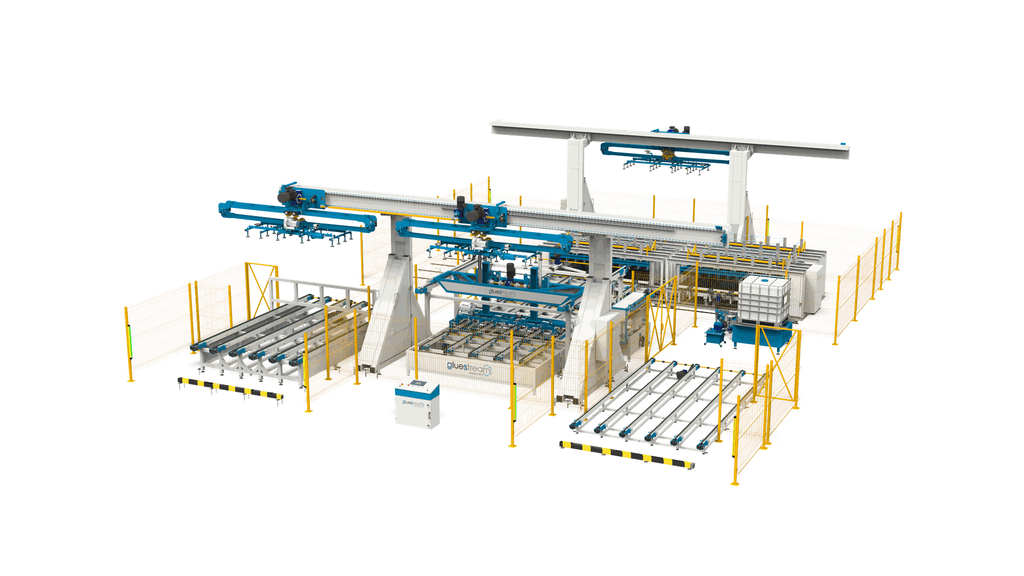

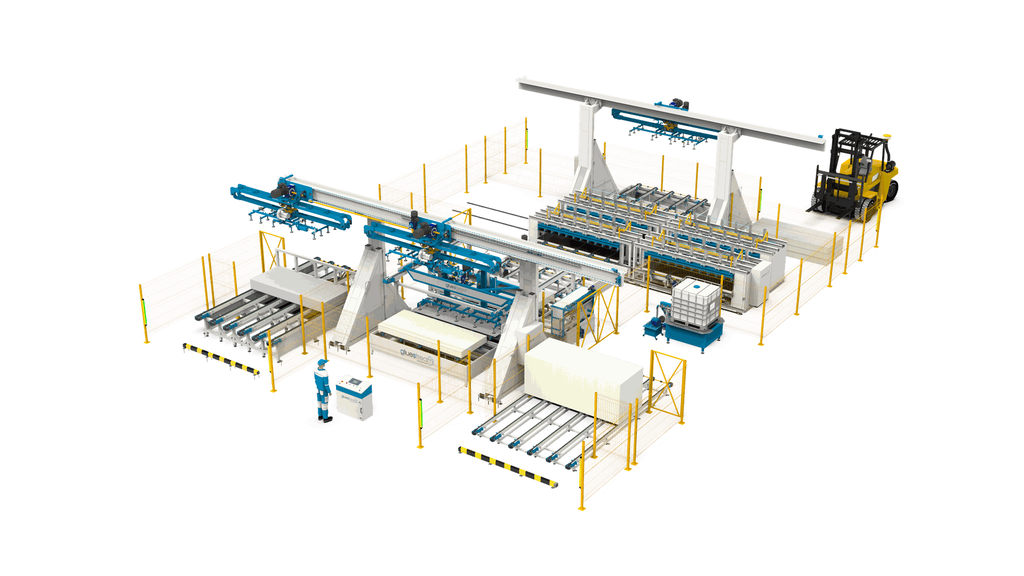

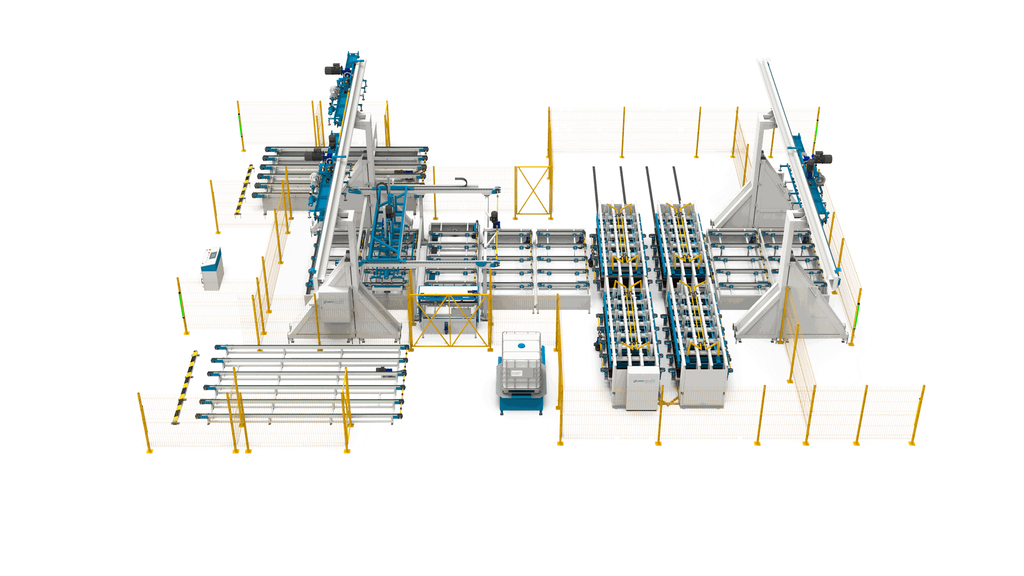

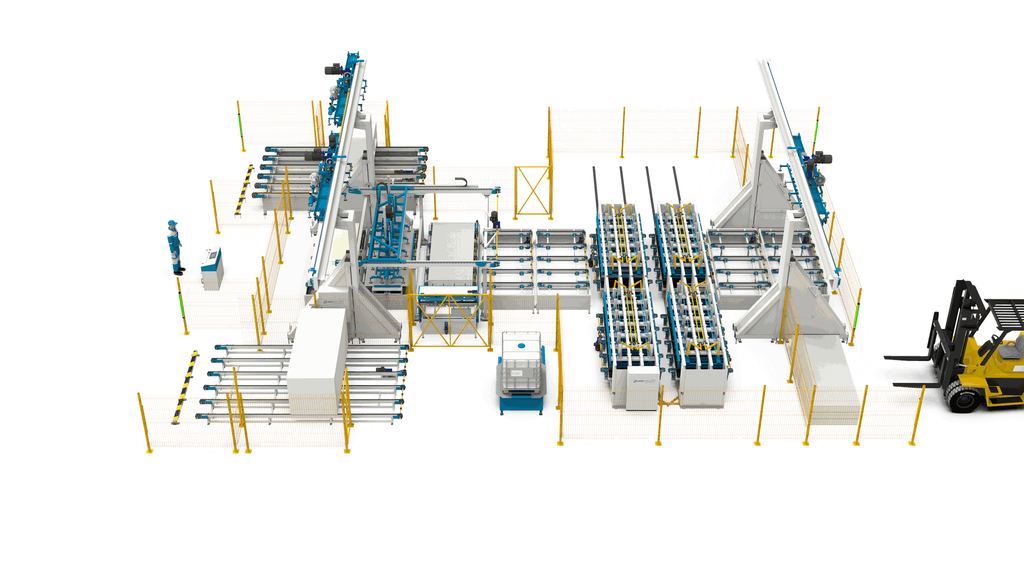

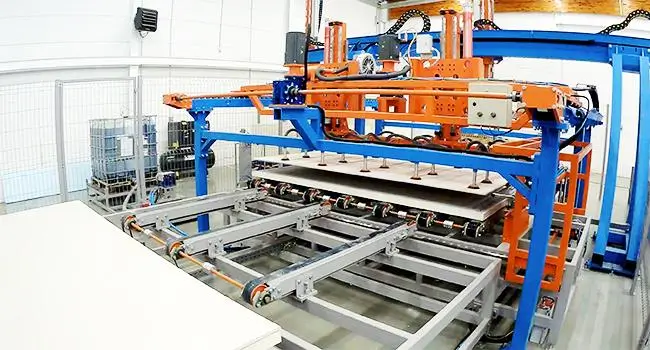

ASPL-4.1 BFT fully automatic insulation panels production line

ONE-COMPONENT MOISTURE CURING PU APPLYING TECHNOLOGY

| Shipping: 24 weeks |

| Personnel: one worker and a forklift driver |

| Production capacity, per 8h shift: 250-300 panels |

| Power supply: according to the region |

| Compressed air: 6-8 bar |

| WiFi module: YES, with 24/7 technical support |

DESCRIPTION

The panel manufacturing equipment includes the following components:

1. Feeding Conveyors: These are equipped to hold materials placed on pallets.

2. Automatic Manipulating Portal: The portals transfer materials from the pallets to the adhesive application area.

3. Automatic Adhesive Applying Portal: Equipped with a high-precision manipulator, it assembles panels with an accuracy of 0.2 mm.

4. Pneumatic Press: Four presses are used in the pressing process.

5. Automatic Manipulators: Designed to move completed panels back onto pallets.

6. Personnel: The operation requires two employees, an operator and a forklift driver.

The production capacity must be calculated for each type of panel and can be adjusted based on customer requirements and the technological process.

Here are the main panel types produced on the line:

1. Plasterboards combined with PIR boards for internal insulation of ceilings and roofs;

2. Particle boards or OSB bonded with PIR boards or EPS boards for the roof and wall insulation;

3. MgO boards and cement boards paired with PIR boards or EPS boards for roof insulation and wall insulation.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please contact us if you need to get our technical support, and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products

If you're interested in getting help with choosing equipment and need our assistance with generating a purchase inquiry or any other specific questions, feel free to contact us!