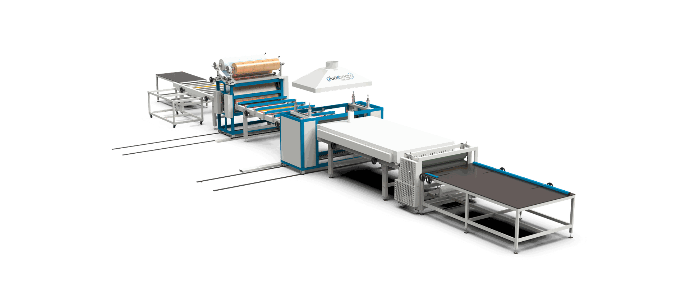

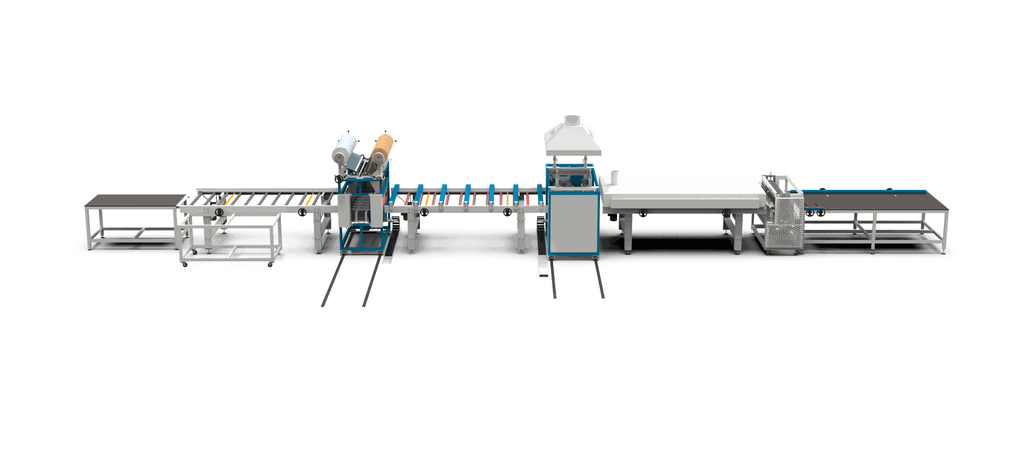

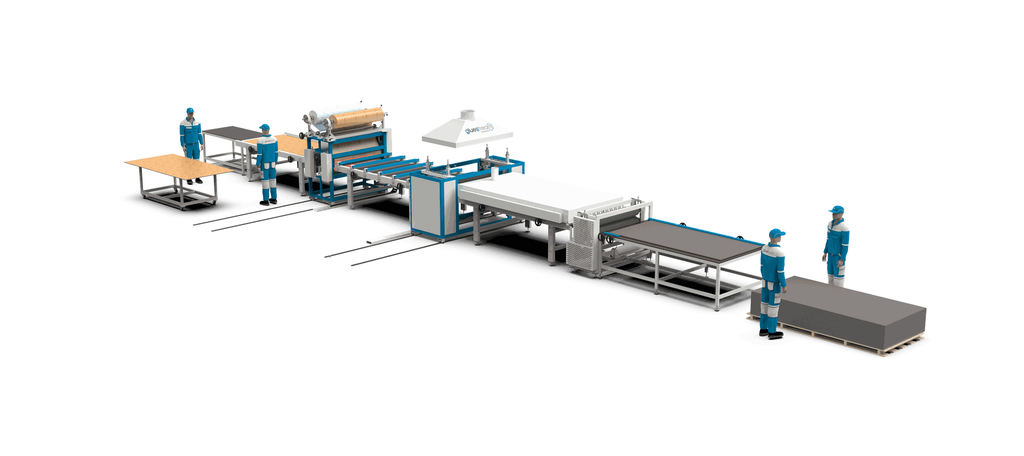

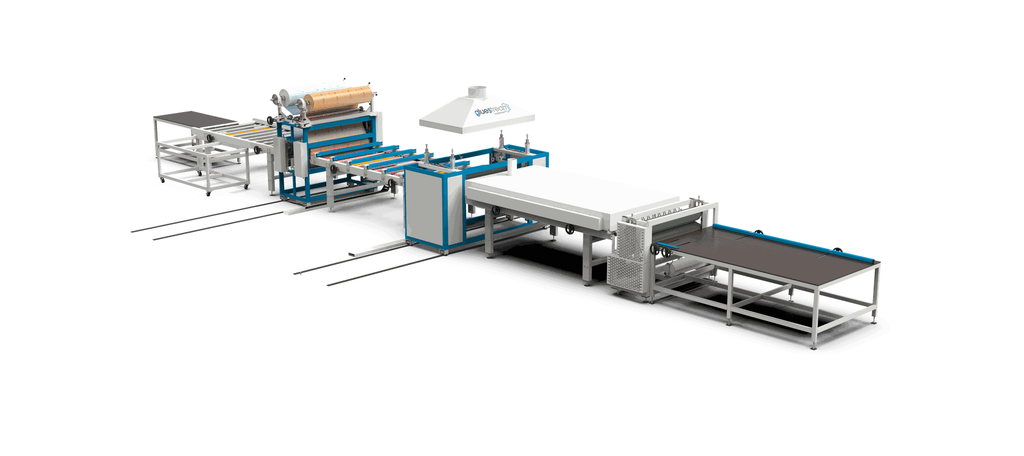

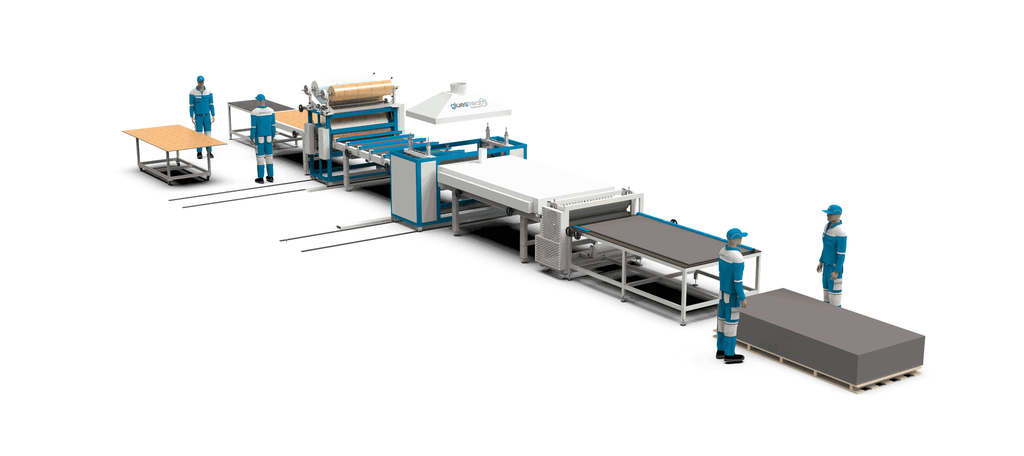

FLM-1320.HM PUR flat laminating machine

Technology: HOT MELT PUR ADHESIVE LAMINATION TECHNOLOGY

| Shipping: 16-18 weeks |

| Personnel: four workers and one forklift driver |

| Glue-applying speed sq.m/min: 10-15 |

| Power supply: according to the region |

| Compressed air: 6-8 bar |

| WiFi module: YES, with 24/7 technical support |

DESCRIPTION

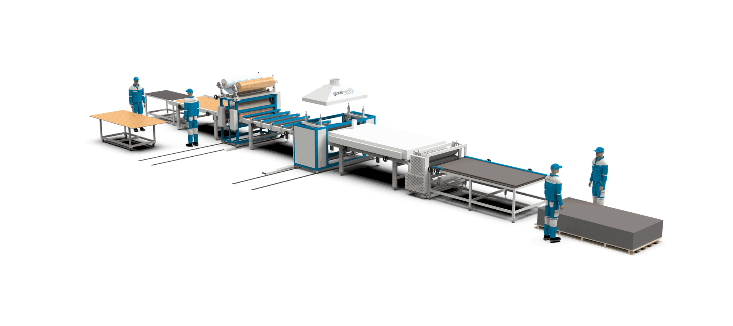

Machinery Design and Components

The machinery design consists of the following key components:

• Primer Processing Automatic Station

• Heating and Drying Tunnel

• Hot Roll Applicator

• Decorative Film Applying System with a Heated Roller Press

• Protective Film Applying Unit

• Feeding and Receiving Tables

The liquid primer processing station is equipped with an automatic control system, which regulates the duration and frequency of primer application.

The heated tunnel ensures the evaporation of liquid components from the primer and heats the laminated sheets to the required process temperature, as specified by the technological workflow.

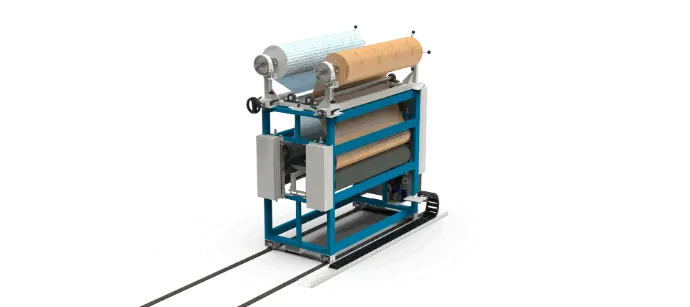

Single-Sided Roll Coater

The single-sided roll coater is equipped with heated dosing and applying rollers, specifically designed for PUR hot-melt adhesive application technology. This ensures precise and uniform glue distribution for high-quality lamination results.

The adhesive application unit features heated rollers with precise glue application adjustment. The machine can be equipped with an additional pre-melting station to enhance productivity or the line can operate without a melting station at speeds up to 3 m/min.

Decorative Film Applying Unit

The decorative film applying unit consists of heated rollers that press the film onto the sheets, ensuring a precise and secure application. The unit is equipped with a film positioning system to guarantee accurate alignment.

The film rolls are secured using pneumatic clamps, and the tension force of the film can be adjusted to achieve optimal application results.

Application of Laminated Sheets

• PVC-laminated sheets are widely used in the production of PVC sandwich panels, which are essential for PVC and aluminum door manufacturing.

• Laminated galvanized steel sheets are commonly used for entrance steel door production. These sheets can undergo further processing such as bending, punching, or laser cutting without causing damage to the decorative film.

Control System and Application

The control system of the laminating line gathers real-time process data from sensors, allowing the operator to monitor and adjust all necessary parameters for optimal performance.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products

If you're interested in getting help with choosing equipment and need our assistance with generating a purchase inquiry or any other specific questions, feel free to contact us!