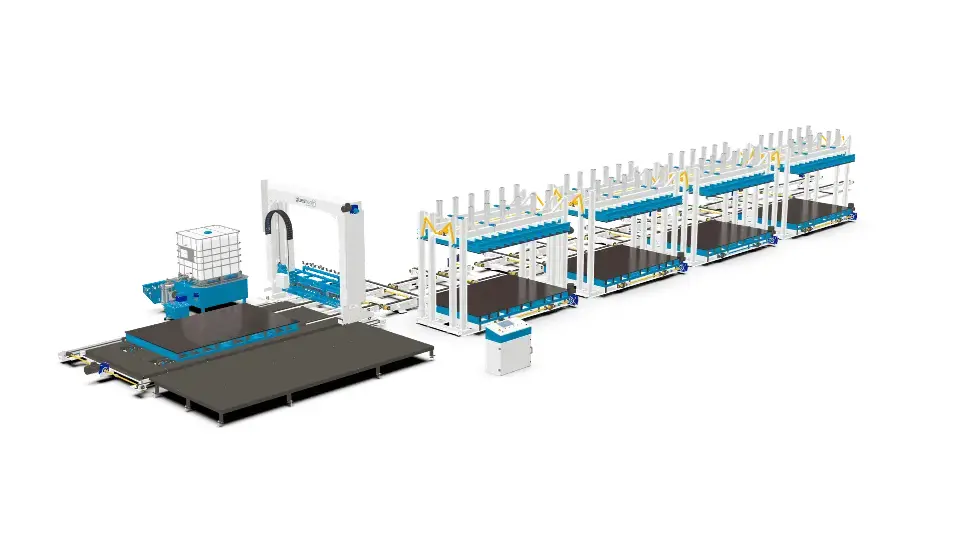

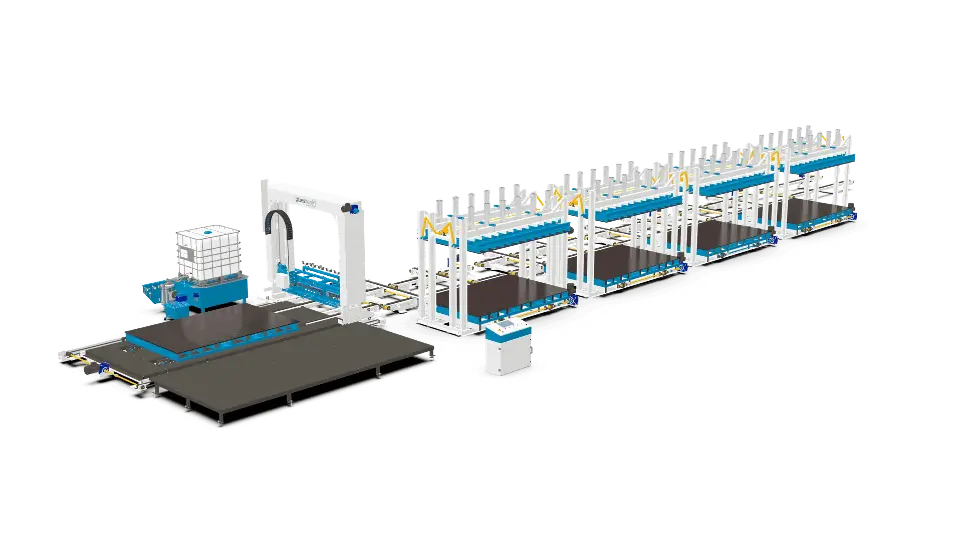

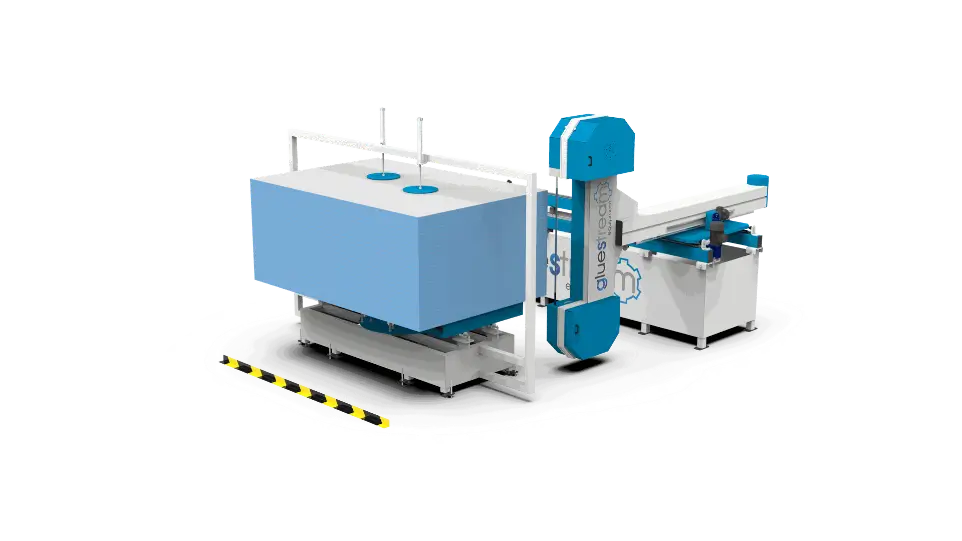

ASPL-10M.1C.PUR.PVC composite sandwich panel production line

Technology: ONE-COMPONENT MOISTURE CURED PU

| Shipping: 16-18 weeks |

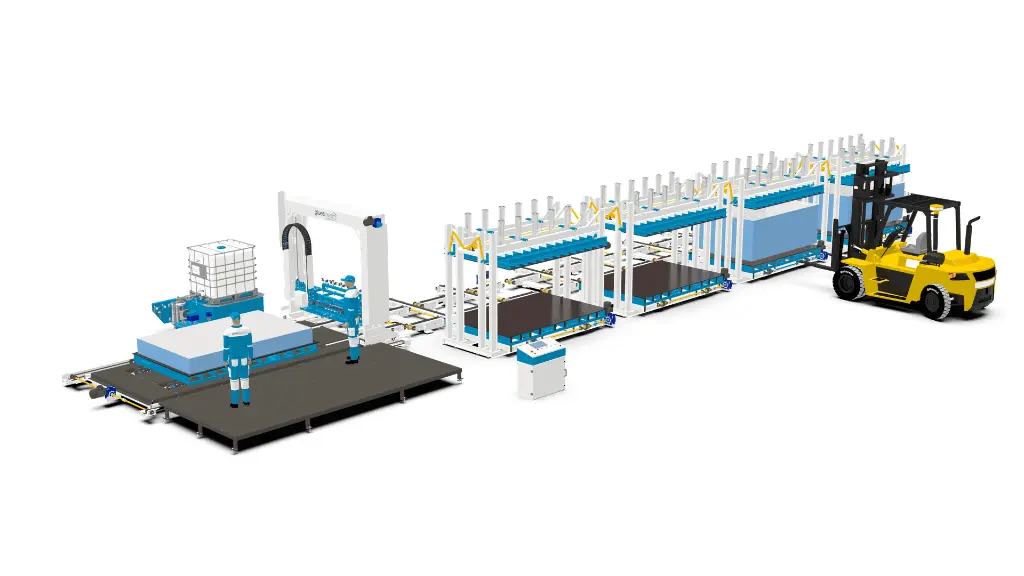

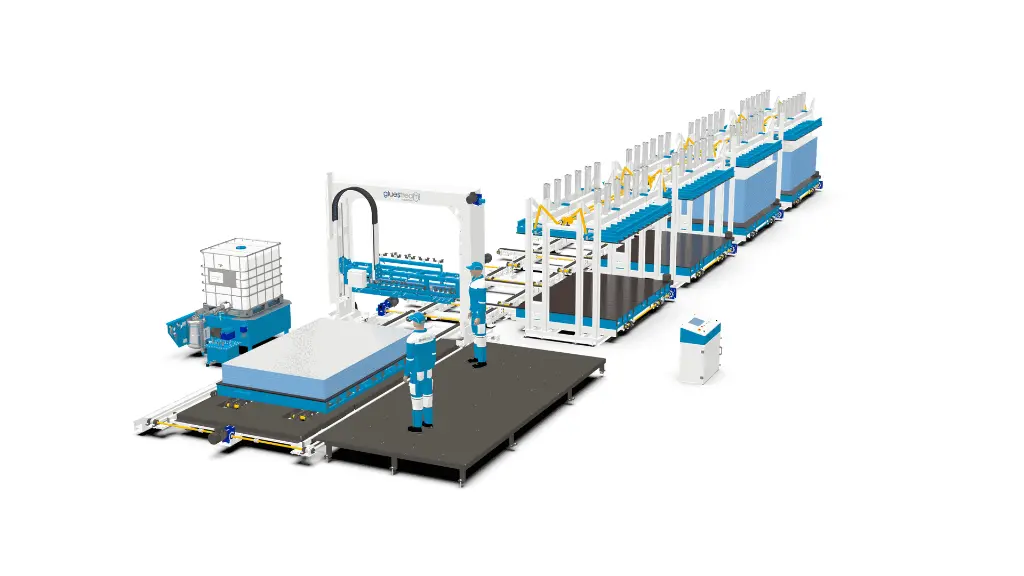

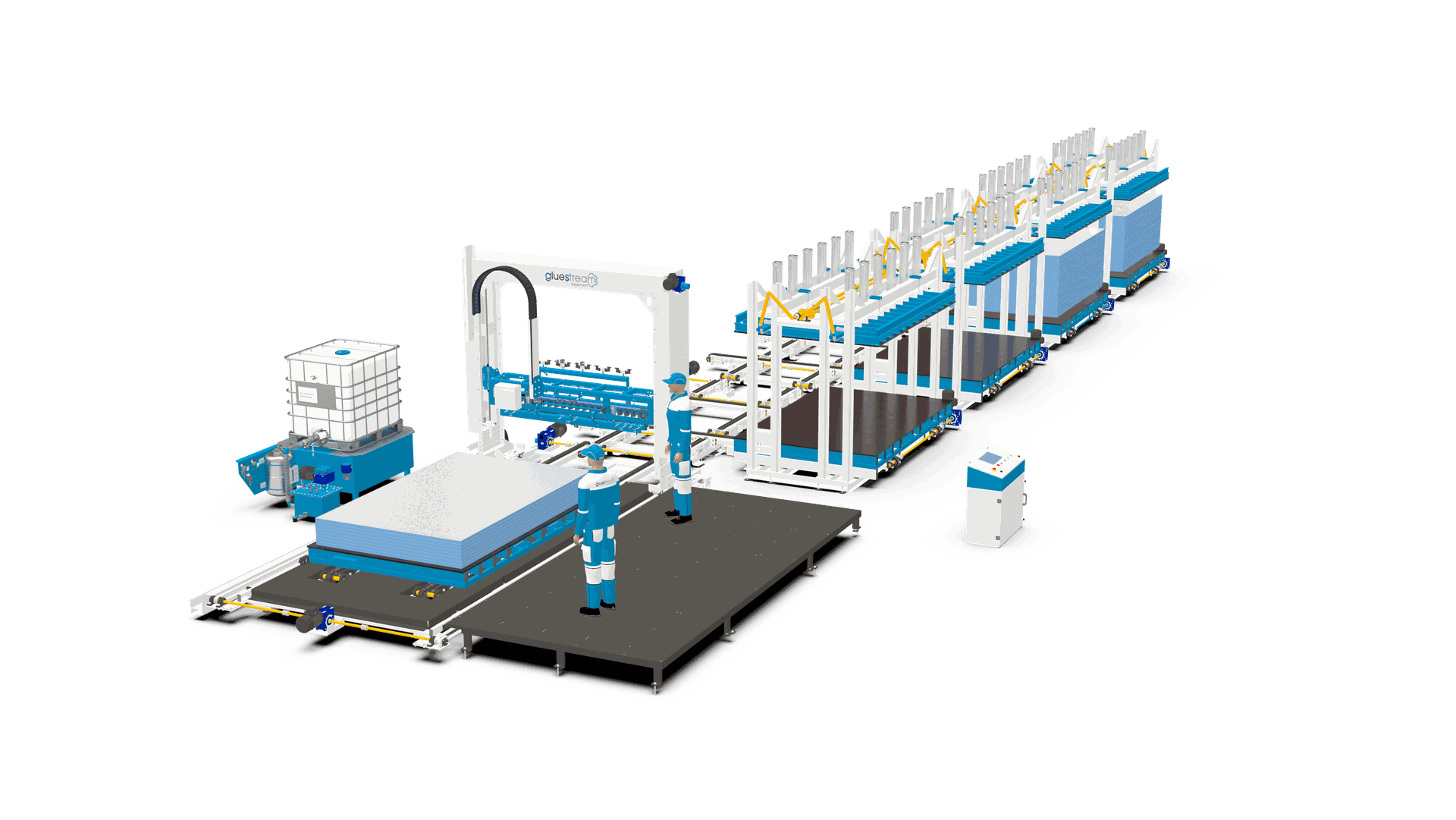

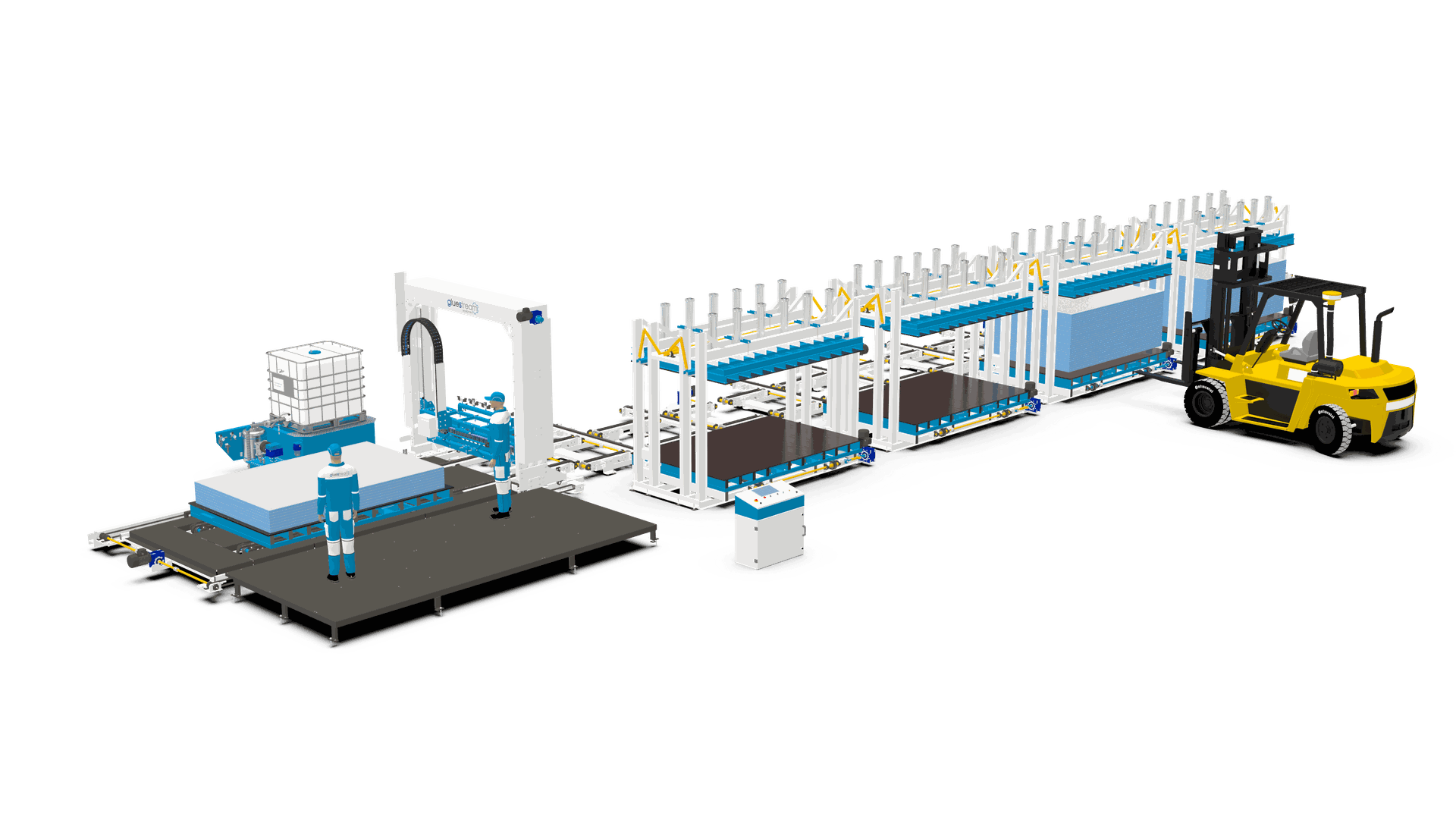

| Personnel: two workers and one forklift driver |

| Production capacity, per 8h shift: 500-600 panels |

| Glue-applying speed sq.m/min: 20-30 |

| Power supply: according to the region |

| Compressed air: 6-8 bar |

| WiFi module: YES, with 24/7 technical support |

DESCRIPTION

Here’s a concise description of the final stage in PVC panel production:

At the final stage, the edges of the PVC panels are trimmed. A console-type band saw moves in the X and Z axes, working with panels up to 2000 x 3050 mm. The table has a mechanism that rotates the stack towards the saw for trimming.

Process:

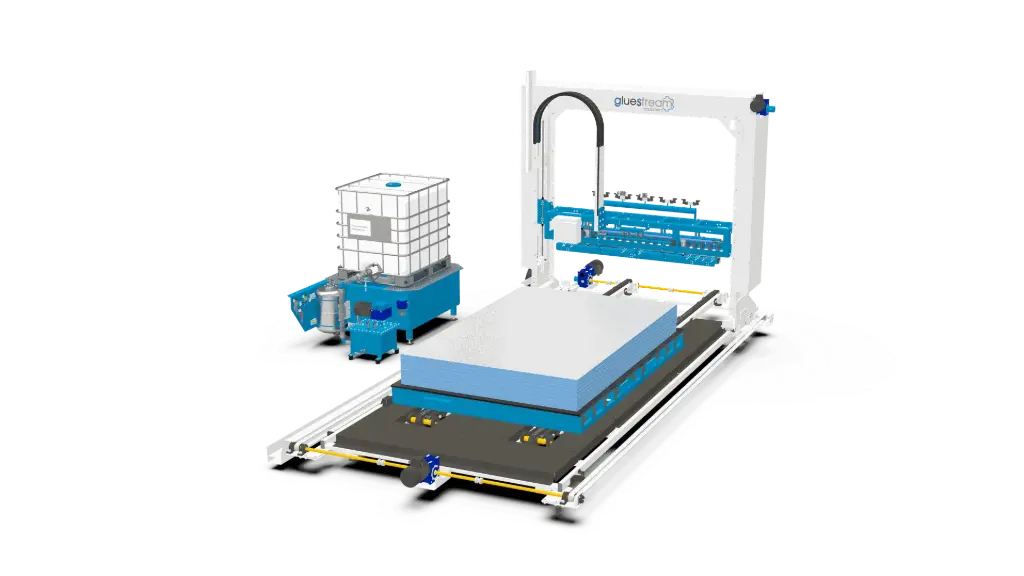

1. Sandwich panels are assembled on a technological carriage.

2. This carriage is mounted on a chain conveyor with the adhesive application unit above.

3. Once assembled, the stack moves on the carriage via the chain conveyor into the press.

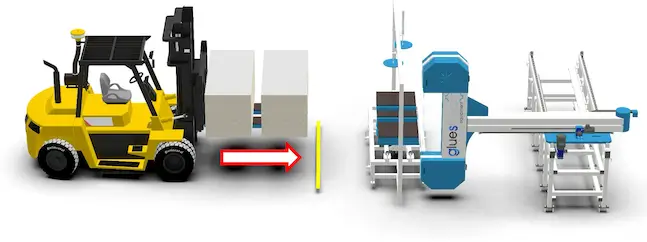

4. After pressing, a forklift unloads the stack from the press and places it on the band saw’s rotary table for trimming.

5. The saw trims each side of the stack sequentially.

6. Trimmed panels are then unloaded from the table.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products

If you're interested in getting help with choosing equipment and need our assistance with generating a purchase inquiry or any other specific questions, feel free to contact us!