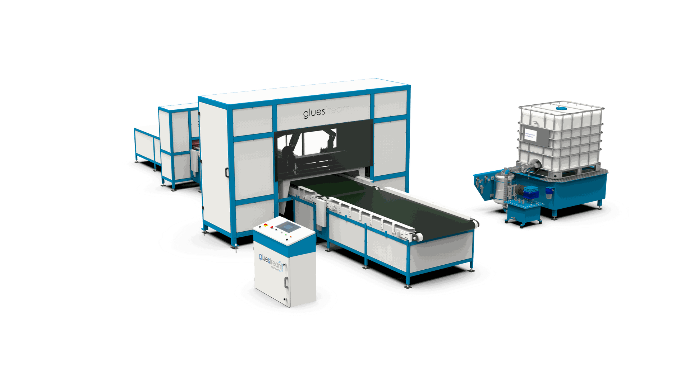

FLM-1100.1-C PUR. Kitchen sponges production line

One-component PUR adhesive spraying technology. Solvent-free, cold curing.

| Shipping: 16-18 weeks |

| Personnel: two workers |

| Glue-applying speed sq.m/min: 10-15 |

| Power supply: according to the region |

| Compressed air: 6-8 bar |

| WiFi module: YES, with 24/7 technical support |

DESCRIPTION

There are such advantages, as:

- solvent-free adhesive technology;

- low glue consumption;

- safety for the personnel;

- low glue cost;

- lower machinery cost in comparison with PUR HOT MELT technology.

There are such disadvantages over PUR hot melt technology:

- it is required to use number of presses depending on the production capacity;

- more production area is required;

- cleaning of the applying heads right after using.

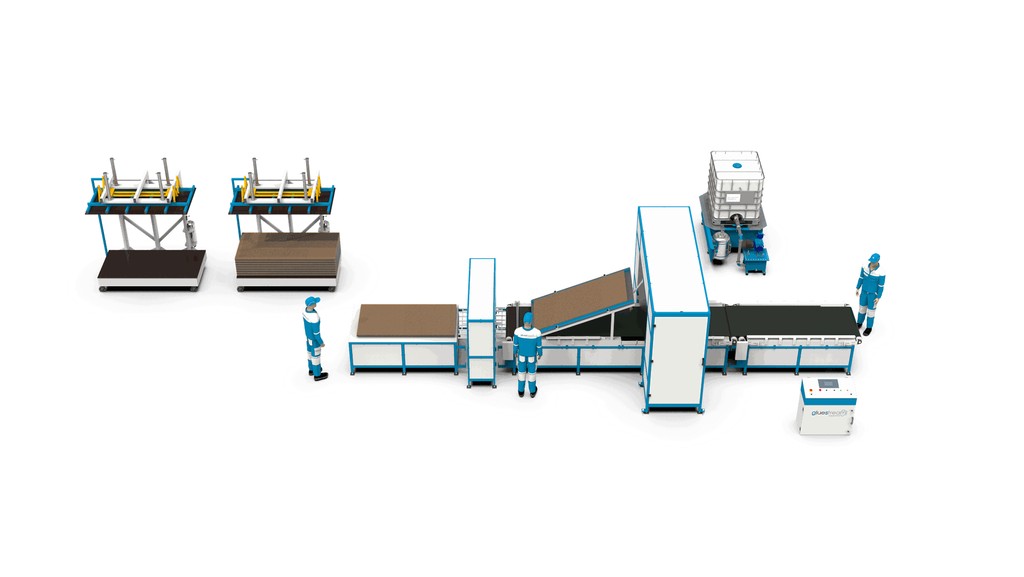

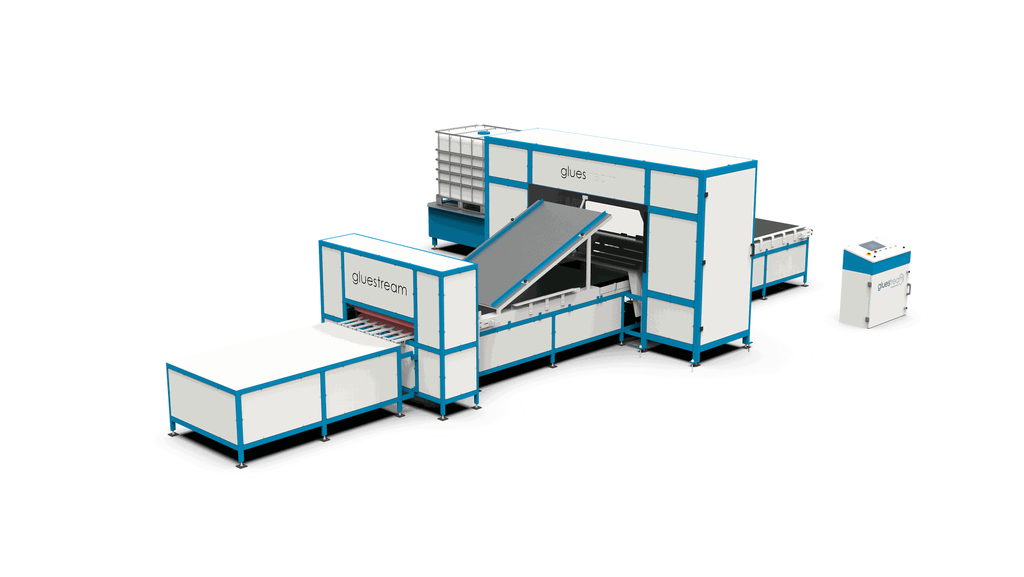

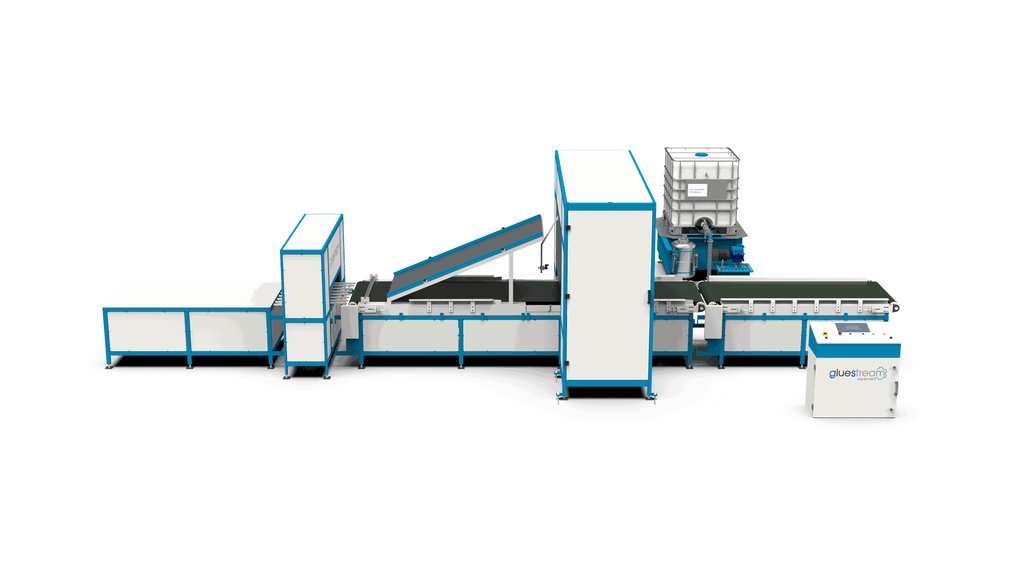

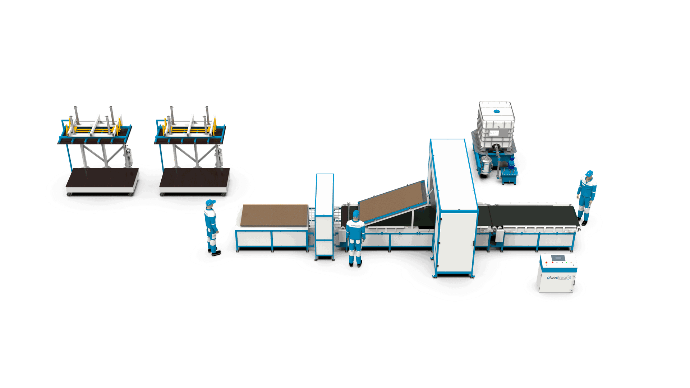

FLM-1100.1C.PUR consists of:

• Belt conveyor for feeding sheet fiber into the adhesive application area;

• Adhesive application unit with movable spray heads;

• Control system;

• Belt conveyor for transporting fiber to the area for supplying elastic polyurethane foam and rolling cylinders;

• Inclined table for supplying elastic polyurethane foam;

• Rolling cylinders (pre-pressing);

• Receiving table;

• Four movable pneumatic presses (final pressing).

The glue is supplied by a high-precision metering pump, applying a precisely defined amount of glue, regardless of the changing of the adhesive viscosity and allowing the use of various types of one-component polyurethane adhesives in accordance with the required technological process.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products

If you're interested in getting help with choosing equipment and need our assistance with generating a purchase inquiry or any other specific questions, feel free to contact us!