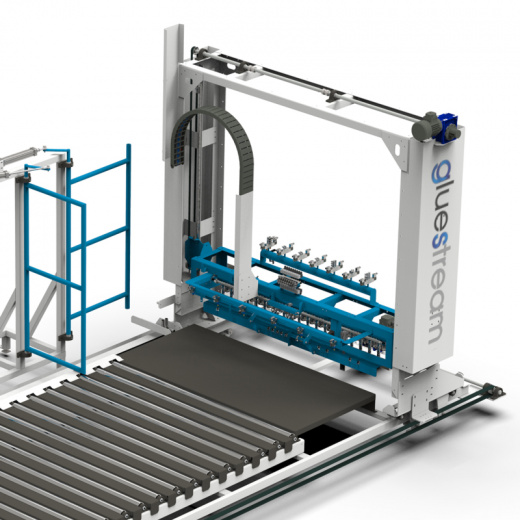

SPL-10M.1C.PUR adhesive-applying portal with an automatic roller conveyor

ONE-COMPONENT MOISTURE CURING PU APPLYING TECHNOLOGY

| Shipping: 6-10 weeks |

| Personnel: two workers |

| Glue-applying speed sq.m/min: 15-20 |

| Power supply: according to the region |

| Compressed air: 6-8 bar |

| WiFi module: YES, with 24/7 technical support |

DESCRIPTION

It is consists of:

- One-Component PUR adhesive applying portal movable under a roller conveyor;

- Pump station;

- Automated roller conveyor;

- Several P-type presses;

- Automated distribution platform, when there are two and more presses.

Glue applying portal can be equipped with one-component PUR applying head or two-component PUR applying head if it is required. One-component PUR adhesive is often used for SIPs manufacturing.

Dimensions of the applying areas are in the range of:

- width - 1000 - 1250 mm;

- length - 0 - 7500 mm;

- height - up to 1200 mm.

The parameters for application may be modified according to the individual requests of our customers.

Dimensions of the glue applying area could be changed:

- automatically by length with a step of 1mm (standardly);

- automatically by height with a step of 1mm (optionally);

- automatically by width with a step of 50mm and more;

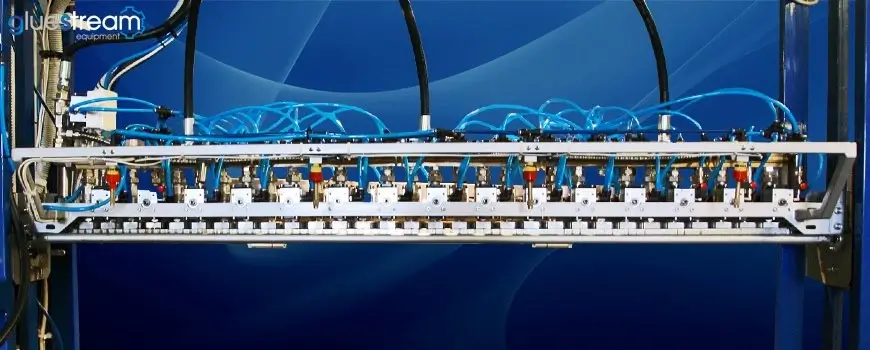

Adhesive applicator KAM-PRO series is equipped with two-way pneumatic valves and a special tray, which is filled with a plasticizer to prevent starting of adhesive reaction inside the nozzles of the applicator. The shutter tray closes automatically, in case of the power failure or machine stop more than one minute (this option can be adjusted according with the Open Time of the used adhesive). Also, it can be closed in manual way by pressing the appropriate key on the control panel.

According to the high accuracy of the positioning and automatic control, it is possible to eliminate the loss of the adhesive.

The adhesive is fed by a high precision dosing pump, applying the accurately determined amount of the adhesive (±5g/m2), leveling difference of the adhesive viscosity and allowing to use 1-component polyurethane adhesives of any manufacturers without reconfiguring the hardware.

Gluestream SPL-10M can be equipped with the necessary amount of P-type presses according to the technological process and level of automation.

All Gluestream machinery is equipped with a remote access module, providing the customer with 24/7 online internet support.

Please, contact us if you need to get our technical support and we will share our knowledge with you.

Our team has a great experience in adhesive technology, gained over the years.

Auxiliary machinery

Glue-laminating equipment is essential in the technological process. Explore which auxiliary machinery our customers have purchased to enhance their operations.

Alternative products

If you're interested in getting help with choosing equipment and need our assistance with generating a purchase inquiry or any other specific questions, feel free to contact us!